UltiMaker PVA Removal Station

No chemicals needed – just add water.

Clean and no-mess

Work with complete peace of mind

Remove PVA up to 4x faster than motionless water

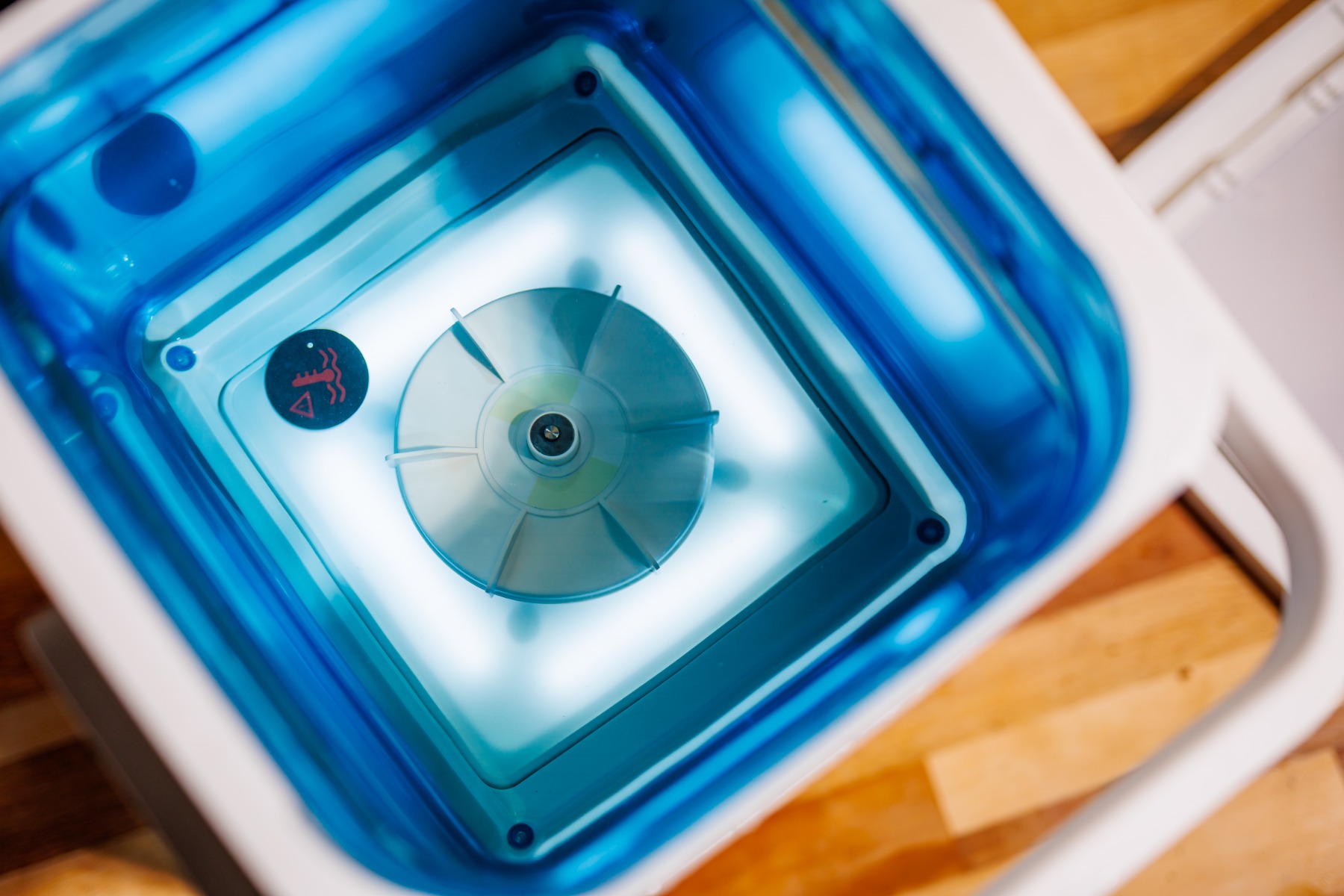

Produce complex parts and stunning visual prototypes quicker and more easily with the UltiMaker PVA Removal Station. Precision-engineered with a magnetic rotor and adjustable speed settings, just add water to dissolve PVA support material in a matter of hours. As part of our 3D printing platform, this start-to-finish solution ensures faster design iterations with minimal operator time.

The UltiMaker PVA Removal Station is an all-in-one solution, reducing operator time up to 80% compared with an improvised PVA removal solution and requiring minimal maintenance or cleaning. Stay focused on more important work while post-processing 3D prints takes care of itself.

The UltiMaker PVA Removal Station features a high-speed dissolving process driven by a magnetic rotor. Compared with motionless water in an improvised container, this circulation removes PVA up to four times faster even from hard-to-reach cavities of complex designs. So you have your parts ready as soon as possible.

ᅠ

Work with less hassle, no mess, and complete peace of mind, thanks to reliable, simple, and easily monitored PVA removal. Just press the start button, leave it to do its job, and continue working with confidence while waiting on a high-quality end result.

Adjust the rotor based on your print with 'normal' speed for regular prints and 'low' speed for those that are fragile or delicate.

A transparent, illuminated container enables you to easily follow the PVA removal process ᄁᄒタᄒモ and know exactly when your part is ready.

A detachable, ergonomically designed container and magnetic rotor allow for easy cleaning so you can stay focused on the job at hand.

Removing PVA with the UltiMaker PVA Removal Station requires no harmful chemicals or additives just use regular tap water, which can be safely disposed of when the removal process is complete.

A top cover (which doubles as a print-transporting tray), a 'park' position for the rinsing basket, and a pouring spout in the container help keep your work environment safe, clean and tidy.

| Manufacturer SKU | 220997 |

|---|---|

| Technology | Fused Filament Fabrication (FFF) |

| Operating Temperature | Operating ambient temperature 15 – 32 °C (59 – 90 °F lbs) Non-operating temperature 0 – 32 °C (32 – 90 °F lbs) Relative humidity 10 – 90% RH non-condensing |

| Power Requirements | Voltage 100 – 240 V AC Frequency 50 – 60 Hz Power 38 W |

| Dimensions | Dimensions 303 x 325 x 374 mm (11.9 x 12.8 x 14.7 in) Dimensions with handle extended 303 x 325 x 528 mm (11.9 x 12.8 x 20.8 in) Net weight 6.35 kg (14 lbs) Container weight (empty) 4.2 kg (9.3 lbs) Shipping box dimensions 400 x 400 x 500 mm (15.7 x 15.7 x 19.7 in) |

| Weight (KG) | 8.5 kg |

| Brand | Ultimaker |

Which materials is the PVA Removal Station compatible with?

The PVA Removal Station has been optimised for the use of PVA in combination with PLA but is also works with other PVA-compatible build materials

What is the maximum size print that fits in the PVA Removal Station?

The rinsing basket can fit parts of maximum 200 x 230 x 165 mm when closed

How long does it on average take to remove the PVA from a print with the PVA Removal Station?

Most PVA support structures will dissolve in 1 – 8 hours, depending on the size and density of the support structure.

What does the water temperature need to be?

It is strongly recommended to not use warm water (above 33 °C) in the PVA Removal Station.

How often does the water in the PVA Removal Station need to be refreshed?

It is possible to use the water in the PVA Removal Station for more than one print or cycle, but higher PVA saturation levels of the water negatively impact the efficiency. Using fresh water will speed up the cleaning process.

What is the best way to dispose water of the PVA Removal Station?

PVA is a biodegradable material and can be disposed of down the drain, providing the wastewater distribution network is connected to a wastewater water treatment plant. Check local regulation and refer to the PVA Removal Station used manual for more details.

Does the PVA Removal Station impact the strength and performance of materials that are sensitive to moisture (e.g. nylon)?

The PVA Removal Station doesn’t impact prints in any other ways than water in and improvised container setup would do. Nonetheless, moisture sensitive materials can still take up some water when submerged. Nylon can take up a few percent of moisture, leading to a ‘lubricated’, less stiff nylon. Typically, this means a decrease in modulus and much longer elongation. For other materials like (Tough) PLA and PETG, water absorption is minimal (less than 0.5%) and only a small decrease in stiffness might be observed.

DELIVERY BY ADDITIVE-X

BOXES SHIP VIA DPD

Order by 4.30pm Monday to Friday (excl Bank Holidays) and Additive-X will ship your order via DPD the same day. DPD will deliver on working days only.

Depending on your postcode your options at checkout will include DPD NEXT DAY, DPD 12:00 and DPD 10:30 options. Some postcodes will show "DPD TWO DAY".

Shipping to Ireland (Northern or Republic of) is a “DAP” service which means you have to pay any Duty and Taxes. Business customers must email us their EORI and UKIMS numbers.

PALLETS DON'T SHIP VIA DPD - WHAT YOU NEED TO KNOW

Some units can only be shipped safely on a pallet due to weight and/or size. Cut off time for orders shipping by pallet is 1.30pm, that’s because we need to book the job before 2pm.

Pallets are big and they ship on big lorries! If there is any problem with a dustbin-lorry size vehicle accessing your property, you need to let us know and we can request delivery by a smaller 7.5T lorry. If this is the case, then PALLET NEXT DAY may not be available.

Depending on your postcode your options at checkout will include PALLET NEXT DAY, PALLET 2-3 DAYS, PALLET COLLECTION HG4 2RN (organise your own pick-up). Some postcodes will show “PALLET 5-6 DAYS” etc.

Pallet deliveries are between 09.00 and 17.00 and we are unable to give you the ETA in advance.

We use a very reliable local supplier, and the pallets go in to the “Palletforce” network. Currently the network don’t use tracking numbers and you can't track online (coming in 2026). Call or email us to check on a delivery or collection.

UK Mainland - Box Shipping

|

COLLECTION HG4 2RN |

£0.00 |

FREE of charge, Mon-Fri 9-5.30pm Collect from Additive-X, Ripon Call 01765694007 to arrange |

|

DPD NEXT DAY |

£7.80 |

FREE on orders over £100 excl VAT |

|

DPD 12:00 |

£14.40 Excl VAT £12.00 |

UK mainland - excl offshore and extended areas Order by 4.30pm Mon-Fri |

|

DPD 10.30 By 10.30 Next Working Day |

£21.00 Excl VAT £17.50 |

UK mainland - excl offshore and extended areas Order by 4.30pm Mon-Fri |

|

DPD Saturday |

£21.60 Excl VAT £18.00 |

UK mainland - excl offshore and extended areas Order by 4.30pm Fri |

|

DPD Two Day |

£15.00 Excl VAT £12.50 |

2-3 day service - UK offshore and extended areas Order by 4.30pm Mon-Fri |

|

DPD Two Day |

£25.00 Excl VAT £20.83 |

2-3 day service Jersey, Guernsey, Isle of Man Order by 4.30pm Mon-Fri |

|

DPD TO IRELAND |

£25.00 Excl VAT £20.83 |

Requires EORI and UKIMS, customer pays Tax & Duties 2-3 day service |

UK Mainland - Pallet Shipping

|

PALLET COLLECTION HG4 2RN |

£0.00 |

FREE of charge, Mon-Fri 9-5.30pm Call 01765694007 to arrange |

|

PALLET NEXT DAY *order by 1.30* |

£102.00 Excl VAT £85.00 |

Next Day Pallet Service Mon-Fri (excl postcodes in zone 7). Must be booked by 1.30pm. Delivery between 9-5pm |

|

PALLET 2-3 DAYS |

£66.00 Excl VAT £55.00 |

Economy Pallet Service Mon-Fri (excl postcodes in zone 7). Delivery between 9-5pm |

|

PALLETS TO ZONE 7 POSTCODES |

Economy Pallet Service Mon-Fri |

Delivery between 9-5pm |

|

AB, IV1-40,52-52,57+ |

£155.00 |

4-5 Day Delivery |

|

DD |

£135.00 Excl VAT £112.50 |

3-4 Day Delivery |

|

IV41-51,55-56, KA27-28 |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

KW1-14 |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

HS, KW15-17 |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

PA20+ |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

PH1-7, 14 |

£135.00 Excl VAT £112.50 |

3-4 Day Delivery |

|

PH 8-13,15+ |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

ZE |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

IM |

£225.00 Excl VAT £187.50 |

5-6 Day Delivery |

|

IM |

£225.00 Excl VAT £187.50 |

5-6 Day Delivery |

|

PO30-41 |

£155.00 |

5-6 Day Delivery |

|

GY AND JE (EXCL. GY9) |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

PALLETS TO IRELAND, GUERNSEY GY9, JERSEY |

Ask for a Quote |

Need more information on delivery and returns? Please visit our full delivery page.

-

Which materials is the PVA Removal Station compatible with?

The PVA Removal Station has been optimised for the use of PVA in combination with PLA but is also works with other PVA-compatible build materials

-

What is the maximum size print that fits in the PVA Removal Station?

The rinsing basket can fit parts of maximum 200 x 230 x 165 mm when closed

-

How long does it on average take to remove the PVA from a print with the PVA Removal Station?

Most PVA support structures will dissolve in 1 – 8 hours, depending on the size and density of the support structure.

-

What does the water temperature need to be?

It is strongly recommended to not use warm water (above 33 °C) in the PVA Removal Station.

-

How often does the water in the PVA Removal Station need to be refreshed?

It is possible to use the water in the PVA Removal Station for more than one print or cycle, but higher PVA saturation levels of the water negatively impact the efficiency. Using fresh water will speed up the cleaning process.

-

What is the best way to dispose water of the PVA Removal Station?

PVA is a biodegradable material and can be disposed of down the drain, providing the wastewater distribution network is connected to a wastewater water treatment plant. Check local regulation and refer to the PVA Removal Station used manual for more details.

-

Does the PVA Removal Station impact the strength and performance of materials that are sensitive to moisture (e.g. nylon)?

The PVA Removal Station doesn’t impact prints in any other ways than water in and improvised container setup would do. Nonetheless, moisture sensitive materials can still take up some water when submerged. Nylon can take up a few percent of moisture, leading to a ‘lubricated’, less stiff nylon. Typically, this means a decrease in modulus and much longer elongation. For other materials like (Tough) PLA and PETG, water absorption is minimal (less than 0.5%) and only a small decrease in stiffness might be observed.