Markforged Blacksmith Software

-

Verified prints off the print bed – Get known good parts at the point of fabrication. Generate, compare, and automatically store quality reports for any part printed with Blacksmith.

-

Accessible and integrated workflow – Integrate regular part inspection into your additive workflow with a single click. No specialized training or complicated inspection equipment needed.

-

Confirmed fleet conformity – Print consistent, predictable parts across a global fleet. Remove any headaches about part variability.

-

Controlled additive quality process – Establish a standardized process for measuring additively manufactured parts.

-

Expand additive applications – Transition business critical parts from traditional manufacturing to additive manufacturing with increased confidence in part quality.

Markforged Blacksmith is available as a software subscription on all cloud-connected Markforged X7 printers.

Blacksmith is provisioned through over-the-air updates for easy customer access and requires an OEM-certified reference bed calibration.

Markforged has released it's revolutionary tool, Blacksmith, an automated, in-process quality control software for the Markforged Industrial X7 3D printer which gives manufacturers accurate parts, right from the print bed.

Blacksmith learns through AI and connects part design, production, and inspection it is described as an adaptive manufacturing platform that continuously evolves and expands in its capability.

For the first time, the printer is fully aware of the parts it produces. Blacksmith uses in-process part inspection to give customers confidence in the part after every print. By streamlining this workflow, Blacksmith makes the world’s factories more cost-efficient, accelerates time to market and reduces the cost of production.

Blacksmith’s easy-to-use intelligent software harnesses the power of the X7’s existing integrated laser micrometer and a patented smart scanning process to securely measure parts as they are being printed. The part dimensional data is then automatically evaluated against the intended design files. Scanning while printing will enable inspection of the inner part structure and critical features that would otherwise be impossible in a single step after fabrication.

Blacksmith Process

1. Calibrate machine

A series of automated calibration procedures is completed to ensure each printer is operating at the high standards required for Blacksmith.

2. Print & scan part

Blacksmith harnesses the power of the X7’s existing integrated laser micrometer and a patented intelligent scanning process to securely measure parts as they are printed.

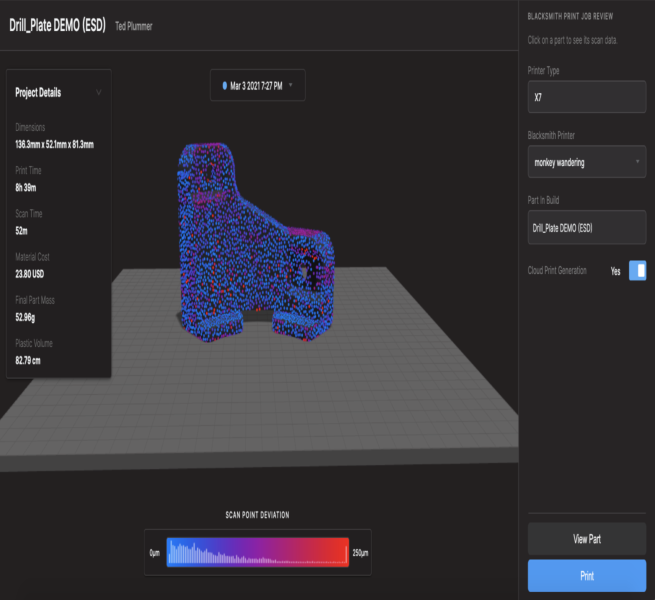

3. Compare scan data to STL

Blacksmith collects measurement data during the print, and assembles a point cloud for review in Eiger. This point cloud is automatically registered and overlaid on the input STL for comparison.

4. Report data

View the deviation across the part’s geometry, and set tolerance limits to assess part quality. The print report is saved in Eiger and can be referenced at any future date.

For further information, please call our Markforged specialists on 01765 694 007

| Software | Eiger |

|---|---|

| Brand | Markforged |

DELIVERY BY ADDITIVE-X

BOXES SHIP VIA DPD

Order by 4.45pm Monday to Friday (excl Bank Holidays) and Additive-X will ship your order via DPD the same day. DPD will deliver on working days only.

Depending on your postcode your options at checkout will include DPD NEXT DAY, DPD 12:00 and DPD 10:30 options. Some postcodes will show "DPD TWO DAY".

Shipping to Ireland (Northern or Republic of) is a “DAP” service which means you have to pay any Duty and Taxes. Business customers must email us their EORI and UKIMS numbers.

PALLETS DON'T SHIP VIA DPD - WHAT YOU NEED TO KNOW

Some units can only be shipped safely on a pallet due to weight and/or size. Cut off time for orders shipping by pallet is 1.30pm, that’s because we need to book the job before 2pm.

Pallets are big and they ship on big lorries! If there is any problem with a dustbin-lorry size vehicle accessing your property, you need to let us know and we can request delivery by a smaller 7.5T lorry. If this is the case, then PALLET NEXT DAY may not be available.

Depending on your postcode your options at checkout will include PALLET NEXT DAY, PALLET 2-3 DAYS, PALLET COLLECTION HG4 2RN (organise your own pick-up). Some postcodes will show “PALLET 5-6 DAYS” etc.

Pallet deliveries are between 09.00 and 17.00 and we are unable to give you the ETA in advance.

We use a very reliable local supplier, and the pallets go in to the “Palletforce” network. Currently the network don’t use tracking numbers and you can't track online (coming in 2026). Call or email us to check on a delivery or collection.

UK Mainland - Box Shipping

|

COLLECTION HG4 2RN |

£0.00 |

FREE of charge, Mon-Fri 9-5.30pm Collect from Additive-X, Ripon Call 01765694007 to arrange |

|

DPD NEXT DAY |

£7.80 |

FREE on orders over £100 excl VAT |

|

DPD 12:00 |

£14.40 Excl VAT £12.00 |

UK mainland - excl offshore and extended areas Order by 4.45pm Mon-Fri |

|

DPD 10.30 By 10.30 Next Working Day |

£21.00 Excl VAT £17.50 |

UK mainland - excl offshore and extended areas Order by 4.45pm Mon-Fri |

|

DPD Saturday |

£21.60 Excl VAT £18.00 |

UK mainland - excl offshore and extended areas Order by 4.45pm Fri |

|

DPD Two Day |

£15.00 Excl VAT £12.50 |

2-3 day service - UK offshore and extended areas Order by 4.45pm Mon-Fri |

|

DPD Two Day |

£25.00 Excl VAT £20.83 |

2-3 day service Jersey, Guernsey, Isle of Man Order by 4.45pm Mon-Fri |

|

DPD TO IRELAND |

£25.00 Excl VAT £20.83 |

Requires EORI and UKIMS, customer pays Tax & Duties 2-3 day service |

UK Mainland - Pallet Shipping

|

PALLET COLLECTION HG4 2RN |

£0.00 |

FREE of charge, Mon-Fri 9-5.30pm Call 01765694007 to arrange |

|

PALLET NEXT DAY *order by 1.30* |

£102.00 Excl VAT £85.00 |

Next Day Pallet Service Mon-Fri (excl postcodes in zone 7). Must be booked by 1.30pm. Delivery between 9-5pm |

|

PALLET 2-3 DAYS |

£66.00 Excl VAT £55.00 |

Economy Pallet Service Mon-Fri (excl postcodes in zone 7). Delivery between 9-5pm |

|

PALLETS TO ZONE 7 POSTCODES |

Economy Pallet Service Mon-Fri |

Delivery between 9-5pm |

|

AB, IV1-40,52-52,57+ |

£155.00 |

4-5 Day Delivery |

|

DD |

£135.00 Excl VAT £112.50 |

3-4 Day Delivery |

|

IV41-51,55-56, KA27-28 |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

KW1-14 |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

HS, KW15-17 |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

PA20+ |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

PH1-7, 14 |

£135.00 Excl VAT £112.50 |

3-4 Day Delivery |

|

PH 8-13,15+ |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

ZE |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

IM |

£225.00 Excl VAT £187.50 |

5-6 Day Delivery |

|

IM |

£225.00 Excl VAT £187.50 |

5-6 Day Delivery |

|

PO30-41 |

£155.00 |

5-6 Day Delivery |

|

GY AND JE (EXCL. GY9) |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

PALLETS TO IRELAND, GUERNSEY GY9, JERSEY |

Ask for a Quote |

Need more information on delivery and returns? Please visit our full delivery page.