The Formlabs Form 4 has a build volume of 20.0 x 12.5 x 21.0 cm (7.9 x 4.9 x 8.3 inches), translating to 5.25 litres of printable space – a 29.6% increase in printable volume compared to its predecessor, the Form 3.

What does that mean for you? Simply, you can pack more parts into one print session and accommodate larger models. The only Formlabs printers with larger build volumes are in the L series (check out the 3L).

Comparison to other 3D Printers

The Form 4’s build volume is competitive compared to desktop resin 3D printers.

However, it’s important to note that build volumes can vary greatly depending on the printer type and intended use. Large-format resin or FDM (Fused Deposition Modeling) printers may offer larger build volumes for specific applications.

Accommodating large-scale prints

The Form 4 is for desktop use, yet it can accommodate larger prints than previous Formlabs models.

For prints taller than 19.0 cm (7.5 inches), you may need to remove the resin tank while removing the build plate and print. This limitation is better than the Form 3/B/+, which requires tank removal for prints over 18.5 cm.

Advantages of a larger build volume in 3D printing

There are several advantages to your 3D printing workflow with a larger build volume:

Higher production capacity and efficiency

Print more parts simultaneously, reducing overall print time per part and increasing production throughput.

Cost and time savings

Printing larger parts as a single piece or multiple parts in a single job reduces material waste, setup time, and post-processing efforts, leading to lower per-part costs and faster turnaround times.

Enhanced prototyping capabilities

Produce larger, more complex prototypes or functional models with fewer assembly steps, accelerating the design iteration process.

Competitive advantage in specific applications

Creating larger parts or higher volumes in a single print job can provide an edge in industries requiring sizeable components or high-volume production runs.

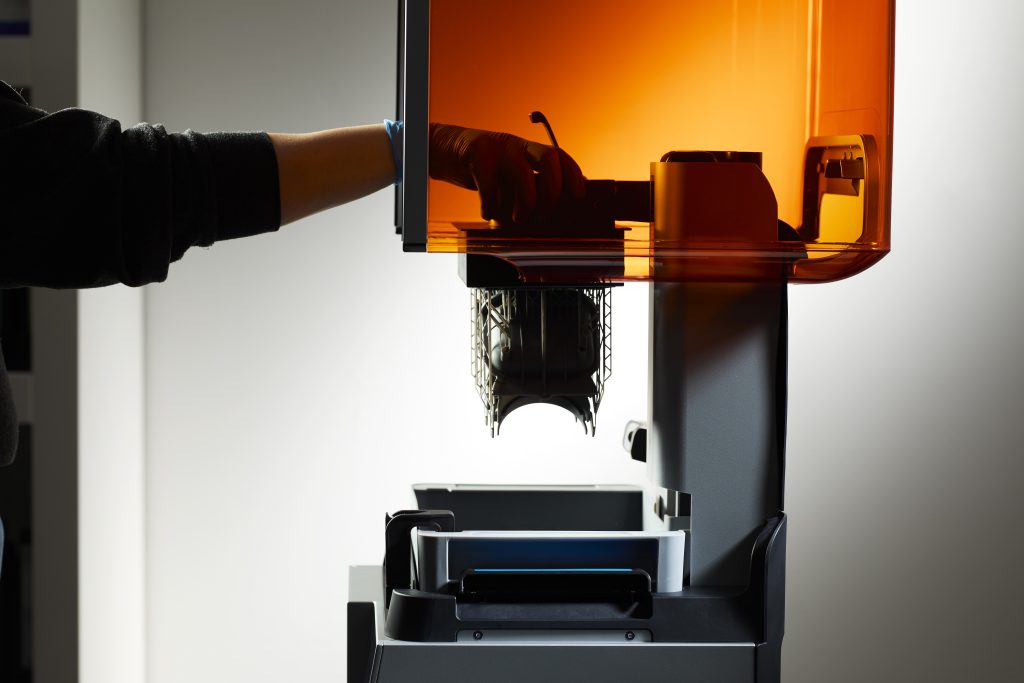

The Form 4’s technology

The Form 4 introduces Formlabs’ Low Force Display (LFD) Print Engine, a next-generation technology that marks a shift from laser-based SLA to Masked Stereolithography (MSLA).

It uses a Backlight Unit with 60 LEDs and collimating lenses, delivering high optical power intensity. The Light Processing Unit 4 features a high-resolution LCD for sharp details and smooth finishes. A proprietary Release Texture and redesigned Flexible Film Resin Tank work together to minimise peel forces during printing.

This combination of advanced components enables faster print speeds, improved surface quality, and enhanced reliability while maintaining compatibility with the high-performance resins developed by Formlabs.

Find out more

Contact us to learn more about the Formlabs Form 4.