3D Printing Architecture is transforming workflows with automated model building, rapid prototyping, complex builds, and collaboration channels that allow teams to share ideas and iterate designs within days.

Among the most popular 3D printing technologies, stereolithography (SLA) is the preferred choice for architectural applications.

SLA printers use a laser to cure liquid resin into solid plastic, layer by layer, producing models with exceptional resolution and smooth surface finish.

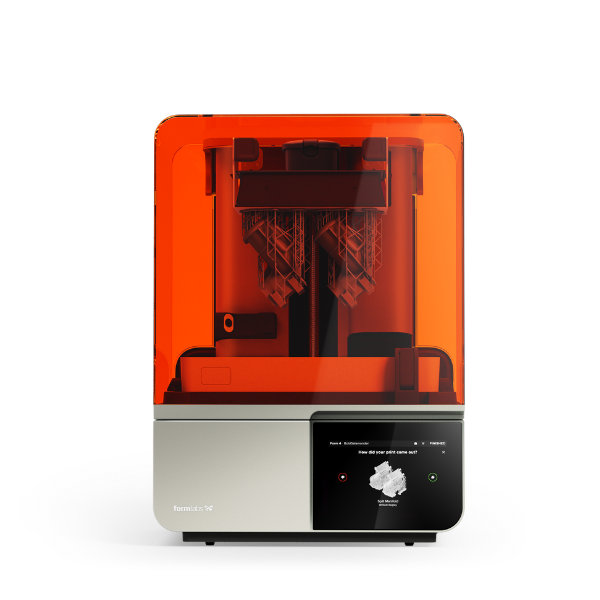

The Formlabs Form 4 is the latest (and some would say greatest) 3D printer for the task. It improves on SLA technology with a custom LCD screen as part of a proprietary Low Force Display (LFD) print engine.

It is a faster and more reliable machine than the Form 3. LFD delivers higher print quality and better material performance than LFS (Low Force Stereolithography) technology and most traditional LCD and SLA 3D printers.

Benefits include:

- Overnight model production accelerates project timelines

- CAD-to-print capability ensures high-precision physical replicas

- Complex geometries become feasible, expanding design possibilities

- Selective modelling clarifies spatial concepts for clients

- Rapid, cost-effective iteration encourages design exploration

3D printing architecture

When most architects consider 3D printing, the biggest draw is producing multiple design iterations at reduced production costs.

Another appealing feature of 3D printing is it lets architects quickly develop and fabricate accurate models, even when projects change rapidly.

Automation and fast build speeds mean intricate parts like stairs, trees, spheres, and curved surfaces that would be time-consuming to manufacture by hand are printable overnight and, in some cases, within just a few hours.

While FFF (Fused Filament Fabrication) is adequate for basic architectural model building, SLA is superior for interior features, undercuts, and thin walls, offering better build speeds, detail, and reliability for complex geometries.

Architecture 3D printing examples and use cases

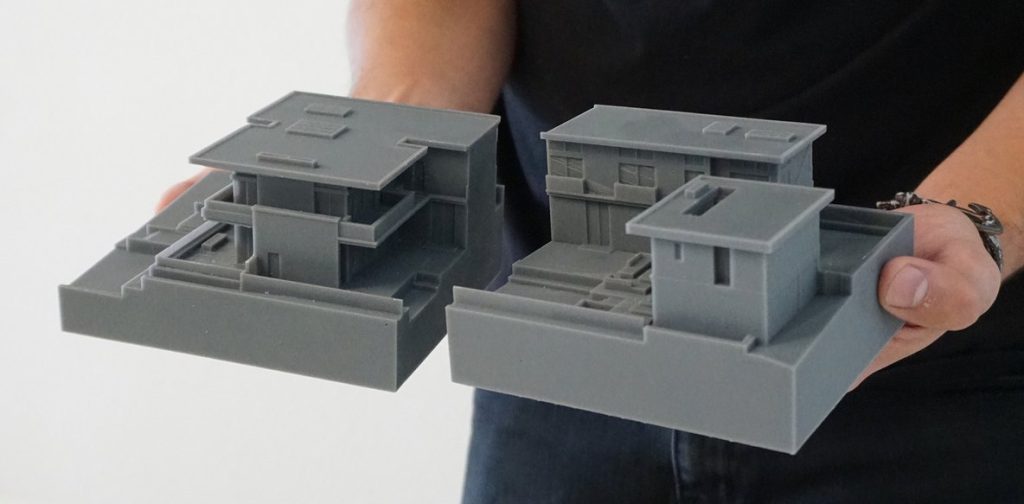

Laney LA

Los Angeles architecture firm Laney LA Laney faced the challenge of effectively communicating complex architectural designs to clients.

Architect Paul Choi introduced 3D printing using a Formlabs SLA printer to address this issue. The solution seamlessly integrated into their CAD workflow, allowing them to produce detailed physical models overnight.

Their process involves creating digital models and then using 3D printing to “freeze” key design moments for client presentations and internal evaluations.

They often highlight specific areas like room layouts, spatial relationships, or site topography in their prints. As a result, Laney LA has enhanced its design process, improved client communication, and gained a marketing edge.

Read the full case study here.

Renzo Piano Building Workshop (RPBW)

RPBW uses 3D printing to create numerous complex architectural models rapidly, often with frequent design changes, for client presentations and internal discussions.

Architects export CAD files, which model makers clean and optimise for 3D printing. They use 3D printing for intricate parts like trees, curved surfaces, and complex joints while employing CNC milling and laser cutting for other components.

Models are often printed overnight, then sanded and painted to match other model elements. The integration of 3D printing has significantly accelerated RPBW’s model-making process, allowing it to produce multiple iterations quickly.

Read the full case study here.

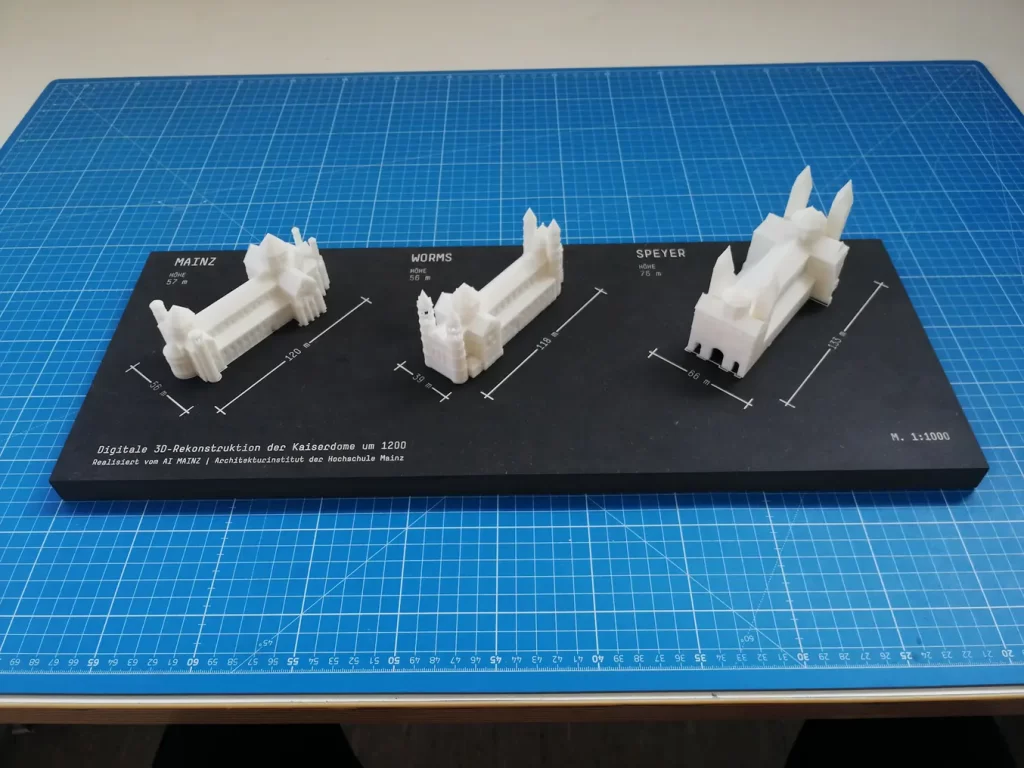

The Institute of Architecture

The Institute of Architecture at the Hochschule Mainz needed to create large-scale, highly detailed reconstructions of three medieval German cities (Worms, Speyer, and Mainz) at two different time periods (800 and 1250 AD) for an exhibition.

They used 5 Formlabs SLA 3D printers to produce over 650 individual segments representing the cities.

The cities were digitally reconstructed based on historical and archaeological data and then divided into a grid of 12x12cm segments.

Each segment was 3D printed using Formlabs White Resin, then washed, support structures removed, sanded, and painted. Segments were printed continuously, with print times ranging from 12 to 24 hours each.

The project successfully created six large-scale models of the cities, showcasing their development over 450 years.

Read the full case study here.

Enhancing Architecture with the Form 4

The Form 4’s Low Force Display (LFD) technology offers several advantages that make it well-suited for architectural applications.

Faster print speeds allow architects to rapidly prototype and iterate on designs, producing multiple versions of models quickly for client presentations or internal reviews.

The highly collimated light and 4K LCD screen ensure sharp details and excellent dimensional accuracy, which are crucial for representing intricate architectural elements like facades, staircases, and complex geometries.

The technology enhances the high-quality surface finish that SLA is known for, reducing post-processing time and producing presentation-ready models directly from the printer.

Plus, the flexible yet strong dual-layer-film tank is compatible with a broader range of materials, including those with higher viscosities, allowing architects to choose materials that represent different elements of their designs.

Features like the integrated resin mixer and optical sensors ensure consistent print quality, reducing the risk of failed prints and wasted time.

Architects wanting to benefit from all these features should consider the Form 4 Premium Package, which includes:

- Build Platform upgrade from standard Platform to Platform Flex x2

- Form Wash (2nd Generation) x2

- Form Cure

- Solvent Pump

- Finishing Tools

- Form 4 Pro Service Plan 3+ Years

It also includes these as part of the Basic package:

- Form 4 printer

- Build Platform

- Form 4 Mixer

- Resin Tank

- Finish Kit

Summing up

Architects are revolutionising their workflows with 3D printing. They use this technology to rapidly prototype designs, create highly detailed presentation models, and explore complex geometries that were previously challenging to visualise.

If you want to do the same but you’re unsure where to start, contact us.

Discover how 3D printing transforms architectural workflows, enabling rapid prototyping and complex model creation. Learn about SLA technology and the Form 4.