The strongest resin for the Formlabs Form 4 in 2024 is Rigid 10K Resin, a glass-filled, extremely stiff material with similar performance to glass and fibre-filled thermoplastics, designed to maintain structural integrity under any condition

Rigid 10K Resin has an extremely impressive strength profile similar to PEEK in stiffness:

- 88 MPa ultimate tensile strength — ultimate tensile strength is the stress necessary to push a material to deformation. For comparison’s sake, ABS has a maximum ultimate tensile strength of around 75 MPa, and Tough 2000 Resin, another durable material, has a 46 MPa ultimate tensile strength.

- 158 MPa flexural strength — the maximum stress a material can endure before yielding in a bending test. ABS has a max flexural strength of around 60 Mpa, while fibreglass ranges from 80 to 110 MPa. In other words, Rigid 10K Resin is very stiff and unyielding (perfect for load-bearing parts).

Additional stats:

- Flexural Modulus: 3.4 GPa

- Elongation: 5.3%

- Elongation at Break: 5.3% post-cured

- Heat deflection temp: 77 °C

- Tensile Modulus: 4.1 GPa

- Thermal Expansion (0-150 °C): 63 μm/m/°C

When to use Rigid 10K Resin

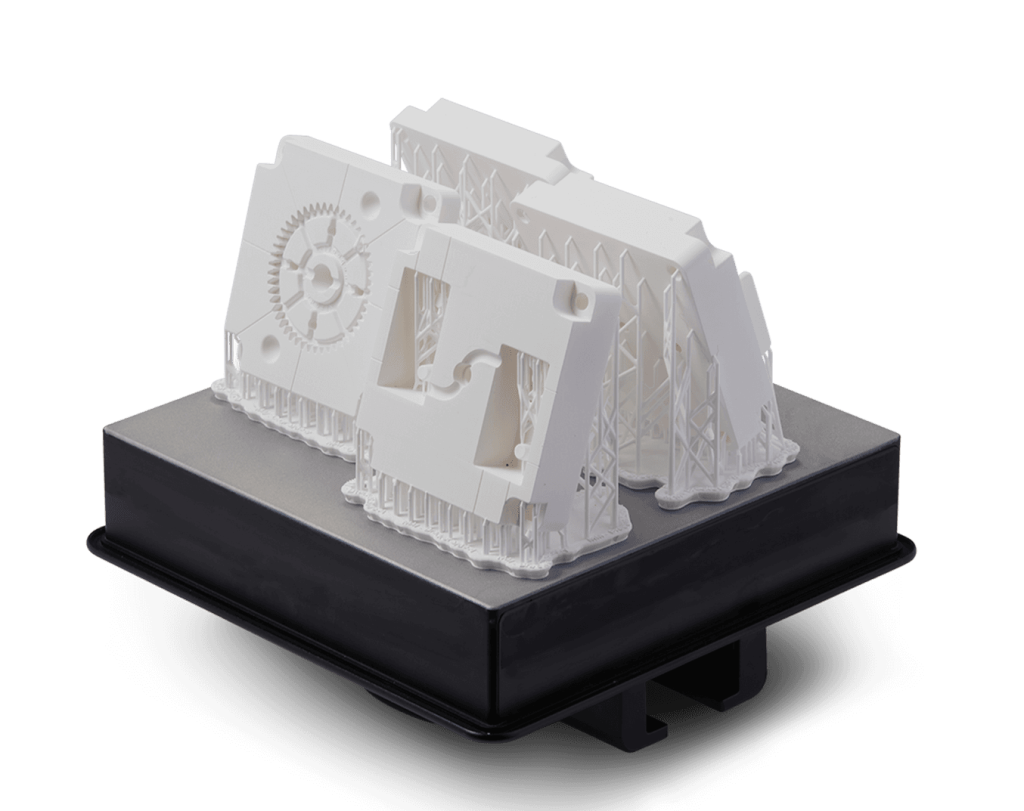

You can use Rigid 10K Resin with your Formlabs Form 4 when you want precise industrial parts that need to withstand significant load without bending. Rigid 10K resin has a smooth matte finish and is highly resistant to heat and chemicals

It’s a fantastic resin for specialised load-bearing parts that shouldn’t bend during use, such as fixing arms, brackets, and other assemblies that need to resist force and pressure in application. It’s also the ideal material for producing moulds for use in injection moulding thermoplastics

How it compares to other strong resins

Rigid 10K Resin is the stiffest and strongest Formlabs Form 4 resin, but it isn’t the only strong and stiff material in Formlabs’ large portfolio:

Rigid 4000 Resin

This is another glass-filled resin which offers similar stiffness to that of PEEK and PEKK thermoplastics but is less brittle, making it less prone to sudden fractures.

Rigid 4000 Resin has a smooth, polished finish and is formulated to fail more slowly than Rigid 10K resin, although it is still incredibly stiff and suitable for general load-bearing applications. It is highly resistant to deformation over time and is great for printing thin walls and features.

Tough 2000 Resin

Tough 2000 Resin simulates the look, performance, and feel of ABS and has an ultimate tensile strength of 46 MPa. It is strong and stiff, perfect for prototyping, and costs less than Rigid 10K Resin for more general applications.

We recommend Tough 2000 Resin for prototyping strong and sturdy parts, especially ones that must withstand impacts and bending.

High Temp Resin

High Temp Resin has a heat deflection temperature of 238 °C @ 0.45 MPa — the highest among Formlabs Form 4 resins. It also has a 49 MPa ultimate tensile strength and an extremely high flexural strength at break of 95 MPa post-cured.

Although it isn’t as strong or stiff, it’s a better choice than Rigid 10K Resin if your parts and assemblies need high-temperature resistance.

Flame Retardant Resin

Flame Retardant Resin is UL 94 Blue Card certified. It’s a self-extinguishing, halogen-free material with excellent flame, smoke, and toxicity (FST) ratings.

It has a 41 MPa ultimate tensile strength and 75 MPa flexural strength – nowhere near the Rigid 10K Resin level, but very good for a flame-retardant material. Use it to manufacture parts, jigs, and fixtures that can’t be set on fire in applications such as:

- Interior parts for aviation, automotive and railway

- Protective and internal consumer electronics components

- industrial environments with high temperatures or ignition sources

Summing up

If you want to 3D print the strongest and stiffest parts with the Formlabs Form 4, Rigid 10K Resin is the most suitable material. Rigid 4,000 Resin comes second, followed by Tough 2,000 Resin, which is cheaper and offers desirable characteristics for prototyping.