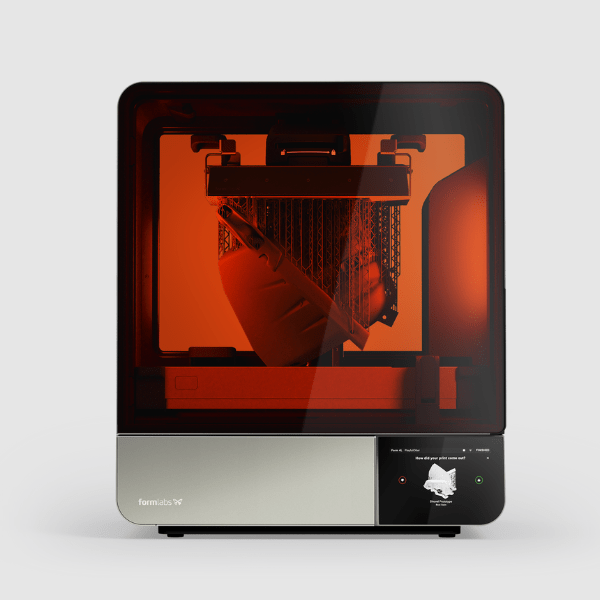

Formlabs SLA printers work with proprietary liquid photopolymer resins developed for these machines. Using the Open Material Mode, some third-party materials are suitable for Form 4 and Form 4L printers with reduced warranty coverage.

Formlabs has created an extensive resin range for applications ranging from prototyping to engineering. Each Formlabs resin is compatible with Low Force Display print engine technology, Formlabs’ newest innovation in SLA technology.

How do Formlabs’ resins compare to other types of 3D printing resins? They are significantly higher quality and designed to simulate common-use plastics such as polypropylene (PP) and thermoplastic polyurethane (TPU).

Join us below to find out more about Formlabs resins.

Printers in this article:

- Formlabs Form 4

- Formlabs Form 4L

- Formlabs Form 4B (for medical resins)

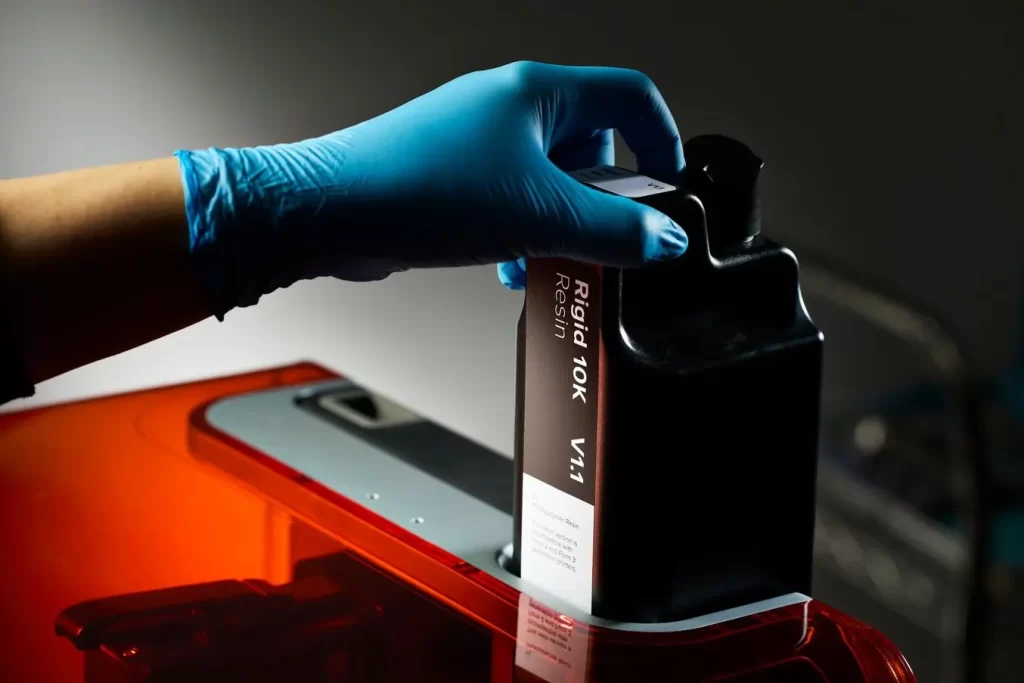

The makeup of Formlabs resins

Formlabs resins contain liquid photopolymers that cure when exposed to light from the printer. The compositions remain confidential for proprietary reasons.

Light at 405 nanometres activates the chemical hardening process in Formlabs resins. The liquid solidifies only where exposed, creating precise parts layer by layer.

Formlabs uses different chemical formulations to adjust each resin type’s hardness, flexibility, and temperature resistance. Of course, you can also manipulate the physical characteristics of your builds by changing the wall and layer thickness.

Open Material Mode

Open Material Mode is an official setting that lets you use third-party 405 nm resins with Formlabs printers. You pay once for a lifetime license, removing restrictions on resin material choices. Educational institutions receive this feature free with printer purchases.

A crucial note is that using non-Formlabs materials may limit warranty coverage for certain equipment failures. Also, it’s only for advanced users who understand how to print with non-Formlabs materials, modify print settings, and debug any resulting issues.

General purpose resins for everyday printing

Grey Resin V5 is the standard prototyping material with balanced mechanical properties and excellent detail capture. It prints significantly faster than previous formulations and eliminates post-curing requirements, reducing production time by hours per part.

Clear Resin V5 produces transparent components suitable for optical applications and fluid visualisation when seeing through parts matters.

White Resin V5 delivers high-contrast surfaces ideal for scanning, photogrammetry, and models where surface feature visibility matters.

Black Resin V5 an exceptionally rich, deep black resin, offering an optimal balance of fast print speed, high accuracy, presentation-ready appearance,

Engineering resins for demanding applications

Rigid 10K Resin provides industrial-grade strength with 88 MPa ultimate tensile strength and 158 MPa flexural strength, matching glass-filled thermoplastics. It creates jigs, fixtures, and functional components that remain dimensionally stable under continuous load.

High-Temp Resin withstands elevated temperatures, making it suitable for thermal testing equipment and manufacturing tooling. Tough 2000 Resin resembles ABS plastic in performance, creating durable parts that resist impact and fatigue during use.

Specialised resins for various industries

Silicone 40A Resin is a true silicone material rather than a silicone-like polymer. You gain production-ready parts with comparable compression set resistance to moulded silicone components, eliminating tooling costs for prototypes and low-volume parts.

Flame Retardant Resin addresses regulatory requirements for consumer electronics, aerospace, and transportation applications. The material suppresses combustion through halogen-free chemistry while maintaining structural integrity at elevated temperatures.

ESD Resin manages electrostatic discharge through carbon-loaded polymers that create controlled pathways for charge dissipation. Parts printed with this material protect circuit boards and components during manufacturing by preventing sudden discharge events.

Medical and dental materials

BioMed resins undergo additional testing for healthcare applications compared to standard materials. BioMed Clear Resin combines transparency with sterilisation compatibility for surgical guides, medical device prototypes and anatomical models.

BioMed Amber Resin offers high strength for medical equipment components that must withstand sterilisation processes.

Dental LT Clear V2 Resin produces oral appliances that meet biocompatibility standards while withstanding long-term use in demanding mouth conditions. These materials require Form 4B /4BL printers with validated biocompatible workflows.

Choosing the right resin for your application

Print speed requirements significantly affect material selection. Draft Resin prints substantially faster than standard materials, allowing quicker prototyping cycles and speedier production.

Surface finish varies between materials. Black Resin V5 produces matte surfaces, while Clear Resin V5 creates glossy, transparent finishes resembling injection-moulded plastics.

Consider mechanical requirements carefully, as Rigid 10K provides exceptional stiffness but minimal flexibility, while Tough 2000 offers moderate strength with greater elasticity suitable for snap fits.

Post-processing requirements

All Formlabs resins require post-processing for optimal results. For consistent results, wash parts in isopropyl alcohol using Form Wash.

Different resins require varying wash times. Post-curing affects mechanical properties, and each material has unique Form Cure settings.

Many resins need standard curing cycles, while High-Temperature Resin requires additional thermal treatment to reach maximum heat resistance.

Formlabs continues developing new resin formulations with each printer generation. The Form 4 with Low Force Display technology enables faster printing speeds while maintaining precision and reliability throughout the material range.

When using these matched resin-printer combinations, you gain injection-moulded quality with the design freedom of additive manufacturing.

Additional reading: Form 4 3D Printer Maintenance: Best Practices