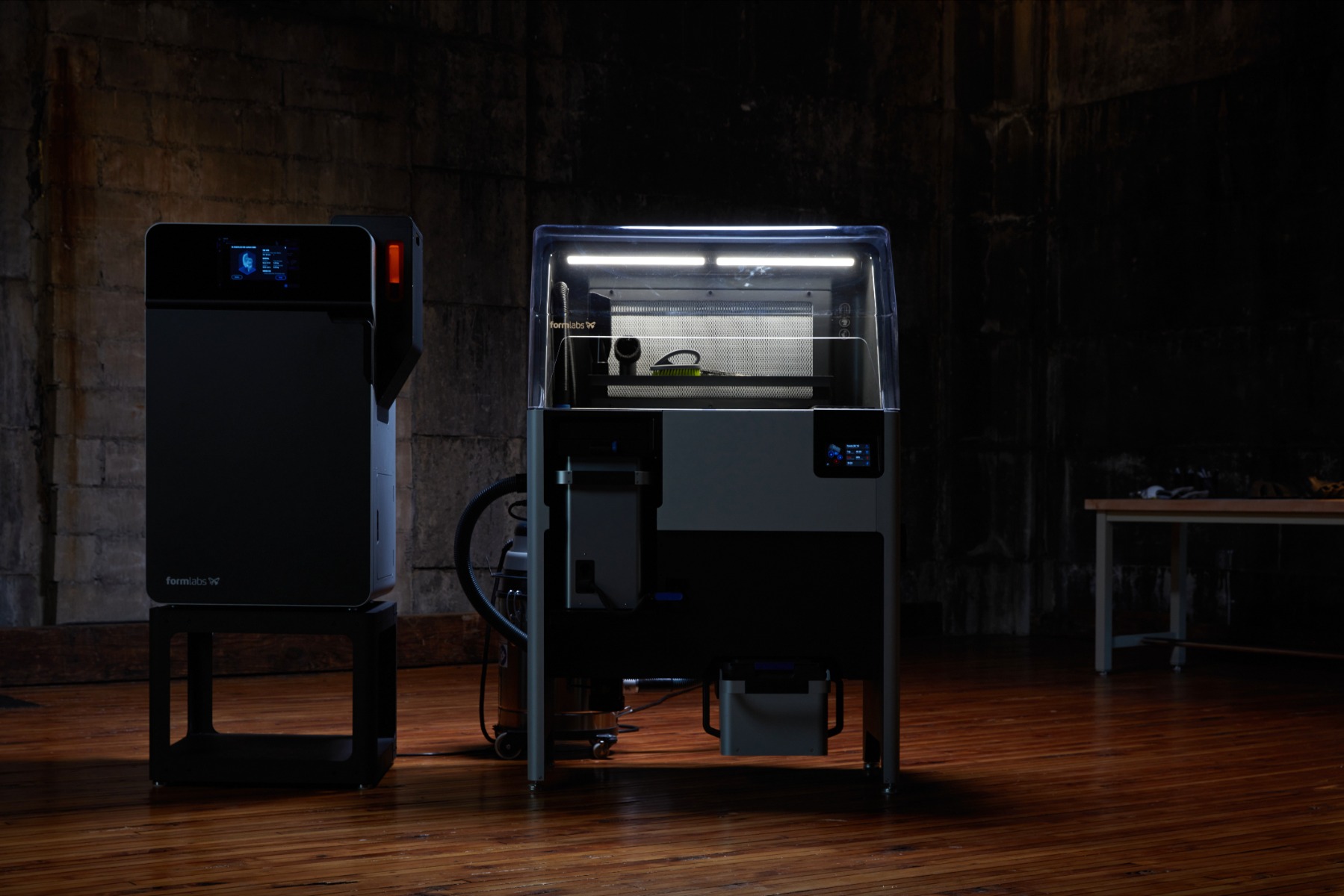

Formlabs Fuse 1+ 30W 3D Printer

- Superior Print Speeds

- Industrial Grade Materials

- Zero Waste, High ROI

Introducing the New Fuse 1+ 30W SLS Printer: Fast Print Speed, High-Performance Materials

Designed for maximum output and minimum waste, Fuse 1+ 30W is our compact SLS 3D printer that packs an industrial punch. Unlock unprecedented print speeds and a full range of materials to deliver truly rapid prototyping and production in-house.

Building on effective powder containment and an easy setup, Fuse 1+ 30W is equipped with a powerful, 30W laser enabling same-day delivery of prototypes and end-use parts. Active powder handling unlocks the use of exclusive, new materials such as carbon fiber-reinforced nylon, and a nitrogen purge print option allows for unprecedented performance and consistency across all SLS parts.

Whether you need a functional prototype today or produce hundreds of end-use parts each week, the Fuse 1+ 30W levels up your workflow for better consistency, shorter turnaround time, and higher efficiency.

What's Included

- Fuse 1+ 30W Printer 230V

- Build Chamber 230V

Compatibility

- Fuse Sift

- Powder Cartridge

| Layer Height | 110 microns |

|---|---|

| Build Dimensions | 165 × 165 × 300 mm |

| Materials | Compatible: Nylon 12 Powder, Nylon 12 GF Powder, Nylon 11 Powder, Nylon 11 CF Powder, TPU 90A, Polypropylene Powder |

| Manufacturer SKU | FS1-P30-230V |

| System Requirements | Windows 7 (64-bit) and up Mac OS X 10.12 and up OpenGL 2.1 4 GB RAM (8 GB recommended) |

| Software | PreForm Desktop Software |

| Connectivity | WiFi, USB Stick, USB Cable, Ethernet Cable |

| Technology | Powder Printing (SLS) |

| Operating Temperature | Operating Environment 18 – 28 ºC Internal Temperature Up to 200 ºC |

| Power Requirements | EU: 230 VAC, 7.5 A (dedicated circuit) |

| Dimensions | Printer 64.5 × 68.5 × 107 cm (165.5 cm with stand) |

| Laser Specifications | 247 microns Ytterbium Fiber IEC 60825-1: 2014 certified 1070 nm wavelength Maximum 30 Watts 3.24 mrad beam divergence (nominal, full angle) |

| Supports | No supports |

| Weight (KG) | 120 kg (without build chamber or powder) |

| Brand | Formlabs |

What are the differences between the Fuse 1 and Fuse 1+ 30W?

The Fuse 1+ 30W offers even greater capability than the Formlabs Fuse 1 The Fuse 1+ 30W has an upgraded laser meaning faster print speeds, it is compatible with all of the Formlabs core Nylon materials as well as Nylon 11 CF. With the ability for nitrogen purging for enhanced material performance it is also more efficient and can print with zero waste.

Are spare parts for the Fuse 1 and Fuse 1+ 30W the same?

Spare parts are the same, with notable exceptions including:

DELIVERY BY ADDITIVE-X

BOXES SHIP VIA DPD

Order by 4.30pm Monday to Friday (excl Bank Holidays) and Additive-X will ship your order via DPD the same day. DPD will deliver on working days only.

Depending on your postcode your options at checkout will include DPD NEXT DAY, DPD 12:00 and DPD 10:30 options. Some postcodes will show "DPD TWO DAY".

Shipping to Ireland (Northern or Republic of) is a “DAP” service which means you have to pay any Duty and Taxes. Business customers must email us their EORI and UKIMS numbers.

PALLETS DON'T SHIP VIA DPD - WHAT YOU NEED TO KNOW

Some units can only be shipped safely on a pallet due to weight and/or size. Cut off time for orders shipping by pallet is 1.30pm, that’s because we need to book the job before 2pm.

Pallets are big and they ship on big lorries! If there is any problem with a dustbin-lorry size vehicle accessing your property, you need to let us know and we can request delivery by a smaller 7.5T lorry. If this is the case, then PALLET NEXT DAY may not be available.

Depending on your postcode your options at checkout will include PALLET NEXT DAY, PALLET 2-3 DAYS, PALLET COLLECTION HG4 2RN (organise your own pick-up). Some postcodes will show “PALLET 5-6 DAYS” etc.

Pallet deliveries are between 09.00 and 17.00 and we are unable to give you the ETA in advance.

We use a very reliable local supplier, and the pallets go in to the “Palletforce” network. Currently the network don’t use tracking numbers and you can't track online (coming in 2026). Call or email us to check on a delivery or collection.

UK Mainland - Box Shipping

|

COLLECTION HG4 2RN |

£0.00 |

FREE of charge, Mon-Fri 9-5.30pm Collect from Additive-X, Ripon Call 01765694007 to arrange |

|

DPD NEXT DAY |

£7.80 |

FREE on orders over £100 excl VAT |

|

DPD 12:00 |

£14.40 Excl VAT £12.00 |

UK mainland - excl offshore and extended areas Order by 4.30pm Mon-Fri |

|

DPD 10.30 By 10.30 Next Working Day |

£21.00 Excl VAT £17.50 |

UK mainland - excl offshore and extended areas Order by 4.30pm Mon-Fri |

|

DPD Saturday |

£21.60 Excl VAT £18.00 |

UK mainland - excl offshore and extended areas Order by 4.30pm Fri |

|

DPD Two Day |

£15.00 Excl VAT £12.50 |

2-3 day service - UK offshore and extended areas Order by 4.30pm Mon-Fri |

|

DPD Two Day |

£25.00 Excl VAT £20.83 |

2-3 day service Jersey, Guernsey, Isle of Man Order by 4.30pm Mon-Fri |

|

DPD TO IRELAND |

£25.00 Excl VAT £20.83 |

Requires EORI and UKIMS, customer pays Tax & Duties 2-3 day service |

UK Mainland - Pallet Shipping

|

PALLET COLLECTION HG4 2RN |

£0.00 |

FREE of charge, Mon-Fri 9-5.30pm Call 01765694007 to arrange |

|

PALLET NEXT DAY *order by 1.30* |

£102.00 Excl VAT £85.00 |

Next Day Pallet Service Mon-Fri (excl postcodes in zone 7). Must be booked by 1.30pm. Delivery between 9-5pm |

|

PALLET 2-3 DAYS |

£66.00 Excl VAT £55.00 |

Economy Pallet Service Mon-Fri (excl postcodes in zone 7). Delivery between 9-5pm |

|

PALLETS TO ZONE 7 POSTCODES |

Economy Pallet Service Mon-Fri |

Delivery between 9-5pm |

|

AB, IV1-40,52-52,57+ |

£155.00 |

4-5 Day Delivery |

|

DD |

£135.00 Excl VAT £112.50 |

3-4 Day Delivery |

|

IV41-51,55-56, KA27-28 |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

KW1-14 |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

HS, KW15-17 |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

PA20+ |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

PH1-7, 14 |

£135.00 Excl VAT £112.50 |

3-4 Day Delivery |

|

PH 8-13,15+ |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

ZE |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

IM |

£225.00 Excl VAT £187.50 |

5-6 Day Delivery |

|

IM |

£225.00 Excl VAT £187.50 |

5-6 Day Delivery |

|

PO30-41 |

£155.00 |

5-6 Day Delivery |

|

GY AND JE (EXCL. GY9) |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

PALLETS TO IRELAND, GUERNSEY GY9, JERSEY |

Ask for a Quote |

Need more information on delivery and returns? Please visit our full delivery page.

-

What are the differences between the Fuse 1 and Fuse 1+ 30W?

The Fuse 1+ 30W offers even greater capability than the Formlabs Fuse 1

The Fuse 1+ 30W has an upgraded laser meaning faster print speeds, it is compatible with all of the Formlabs core Nylon materials as well as Nylon 11 CF.

With the ability for nitrogen purging for enhanced material performance it is also more efficient and can print with zero waste.

-

Are spare parts for the Fuse 1 and Fuse 1+ 30W the same?

Spare parts are the same, with notable exceptions including:

- Air Heater

- 30W Laser Assembly