3D printing is an extraordinary manufacturing tool for rapid prototyping and iterative design, and it is cost-competitive with conventional manufacturing methods when you keep costs in check.

The first step to reducing 3D printing costs is getting a great deal on hardware and supplies so that you have a baseline cost to work against.

Materials (filaments, resins, etc.) are critical to source savvily because they represent an ongoing cost that increases with scale.

Spending less on hardware, materials, and software subscriptions to lower your investment before you start printing is the best way to save money. Every small saving you make after is a bonus towards reducing your total 3D printing costs.

You can then start optimising 3D printer settings to reduce waste, trial reduced infill percentages, increase layer heights, scale down prototypes, and switch to new materials that are cheaper but offer similar performance.

We’ve put together some helpful tips below to help you save money and reduce 3D printing costs (feel free to skip any you already know).

Let’s jump in!

Choose the right technology

You can optimise your 3D printing process down to a tee, but if the technology and hardware aren’t an ideal fit, you will struggle to bring costs down.

You should compare the three most established 3D printing technologies for plastics – fused filament fabrication (FFF), stereolithography (SLA), and selective laser sintering (SLS).

Here’s what you need to know in a nutshell:

- FFF – best for manufacturing prototypes and parts quickly.

- SLA – best for complex geometries and detail.

- SLS – best for industrial applications and manufacturing lines.

When choosing a 3D printer, consider the following:

- Your use cases and 3D printing requirements.

- The 3D printer’s build volume.

- The 3D printer’s material support.

- Your budget.

- The cost to operate, run, and maintain the printer.

Substitute expensive with cheap materials

FFF 3D printers support an enormous range of thermoplastics limited only by the maximum temperature of the extruder. This means you can substitute an expensive material for a cheaper one, albeit with performance trade-offs in some cases.

Using a cheaper material is a no-brainer if you are prototyping, iterating, or producing parts that do not require specific mechanical characteristics.

Typical materials include:

- PLA

- ABS

- PET-G

- ASA

- TPU

- PC

- Nylon

These standard materials are available from a wide range of brands, and the same goes for the nylon powder used by some SLS 3D printers.

Optimise 3D printer settings

Your 3D printing costs will increase substantially with failed prints and material wastage. Most 3D printers have profiles for different 3D printing materials, but your part design can impact the natural order.

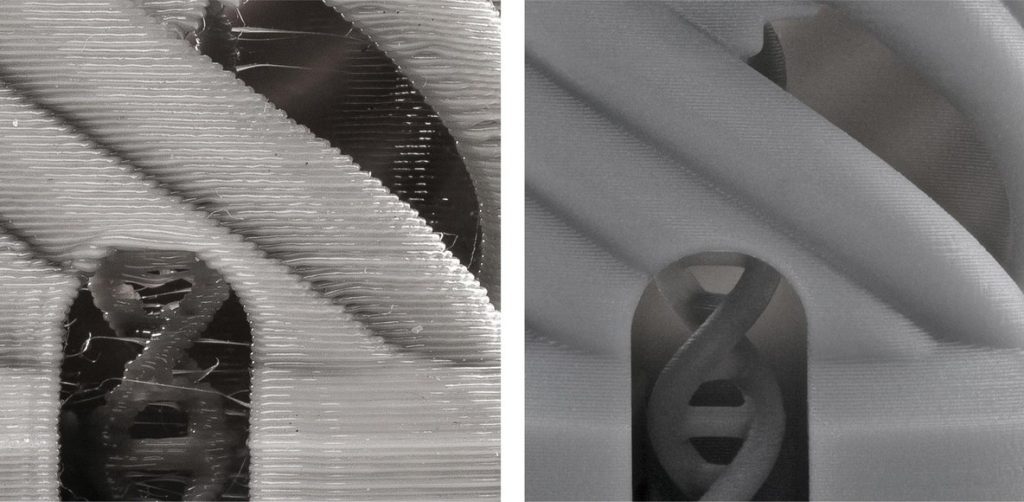

The good news is that 3D printing problems like over-extrusion, under-extrusion, stringing, layer separation, and surface marring are all avoidable with the correct 3D printer settings.

For example, if you have layer separation, you can reduce layer heights to improve interlayer adhesion. We recommend maximum layer heights are 20% smaller than your nozzle diameter (e.g., a 0.32mm layer height for a 40mm nozzle).

If you have curling corners, try a lower print chamber temperature or reduce the extrusion temperature to reduce filament flow.

Most 3D print preparation software offers settings that let you reduce the number of bottom layers and infill percentages with one click. Some software, like Ultimaker Cura, can also track your estimated print costs.

Note that supports structures and infills are editable after CAD/3D modelling, giving you many opportunities to optimise your prints.

Reduce infill percentages

Infill is the structure of the material inside a 3D-printed part. The basic principle is it determines how dense a part is and, in turn, how much material is used to make the part.

We measure infill as a percentage: 0% is hollow, and 100% is solid. Most designers stick to 5% leaps. Standard prints range from 15-50% infill, while functional prints (such as engineering parts) have a 50-100% infill.

You can reduce your cost per part by reducing infill percentages so that less material is printed. Infill is necessary to print structurally sound parts, but you can change the pattern while reducing percentages to maintain strength.

Reducing infill percentages can also increase print speeds, helping you increase throughput and manufacture more high-quality models.

Increase layer heights

Increasing layer heights creates fewer steps for your 3D printer because it has fewer layers to print, speeding up print times considerably. For example, printing at a layer height of 100 microns is up to 50% faster than printing at 50 microns.

While increasing layer height will decrease the resolution and quality of your print, this is not usually a problem for iterative design and rapid prototyping.

You will use the same material volume as you would with more layers, but your print time will be slashed, boosting your throughput potential.

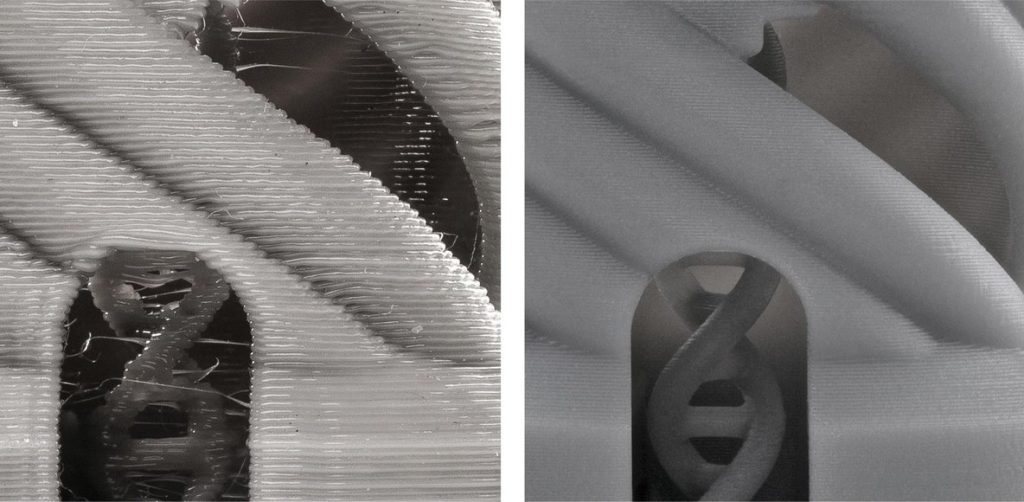

Reduce or eliminate support structures

Support structures drag 3D printing costs higher because they may utilise a secondary material and increase print times.

The biggest reason for unnecessary support structures is improper part orientation, which increases the required support.

Depending on your design, printing with limited or without any support structures might be possible by optimising your 3D printer settings.

However, the most significant improvements are possible with print preparation software like Bambu Studio, which will optimise the most efficient paths.

Try designing your part to have dimensional stability with minimal supports, and use print software to orientate your part efficiently.

Scale down by a few factors

Printing smaller, scaled-down models, where viable, uses less material and reduces print times.

However, you must ensure that wall thickness adjusts in line to be thick enough to be printed. For example, a wall that is 1mm thick reduced by a factor of 4 is now 0.25mm thick – possibly too thin for your printer.

Scaling down while retaining optimal wall thickness can also eliminate the requirement for supports or at least greatly minimise them.

Find out more

For help reducing 3D printing costs, please get in touch with the team at 01765 694 007, email [email protected], or you can