The Formlabs Fuse 1+30W delivers industrial-grade SLS printing without industrial complexity or cost. Your parts emerge in as little as seven hours, and most jobs are completed within 14 hours.

The system combines a powerful 30-watt laser with automated workflows from setup to finished parts, supporting proprietary powders and open material options.

Proprietary materials

Nylon 12 Powder balances strength and detail

Nylon 12 Powder has balanced performance for functional prototyping and end-use production. You gain complex assemblies and durable parts with high environmental stability, making this versatile material suitable for almost any application requiring strength and fine detail reproduction.

Nylon 12 Tough Powder offers superior ductility

With Nylon 12 Tough Powder, your parts benefit from exceptional dimensional accuracy across the build chamber. You receive best-in-class refresh rates among nylon powders alongside high ductility, creating more durable components for prototyping and small batch production with reduced warpage.

Nylon 12 White Powder enables customisable finishing

Nylon 12 White Powder maintains all standard Nylon 12 properties while adding finishing flexibility. You can easily dye printed components to match brand aesthetics or create medical models with high contrast and detail, perfect for customer-facing parts requiring visual customisation.

Nylon 11 Powder excels with thin walls

Nylon 11 Powder creates highly ductile, robust parts with superior flexibility compared to Nylon 12. Your thin-walled designs print more successfully as this material demonstrates less brittleness and better flexibility, making complex geometries with fine features more feasible.

TPU 90A Powder creates flexible, skin-safe components

TPU 90A Powder combines high elongation with superior tear strength for flexible parts. Your prototypes and end-use components remain skin-safe while withstanding everyday demands. Thanks to the 20% refresh rate this material offers, you benefit from remarkably low costs.

Nylon 12 GF Powder increases stiffness and stability

Glass-filled Nylon 12 GF Powder enhances stiffness and thermal stability for demanding industrial environments. Your functional prototypes maintain structural rigidity and dimensional stability even at elevated temperatures, making it ideal for mechanical components under thermal stress.

Nylon 11 CF Powder delivers lightweight strength

Nylon 11 CF Powder combines nylon versatility with carbon fibre reinforcement for lightweight, high-performance parts. Your components gain superior strength-to-weight ratios while maintaining exceptional stiffness, perfect for applications requiring impact resistance and thermal stability.

Open material mode

Open Material Mode transforms your Fuse 1+30W into an experimental platform accepting third-party 1064 nm powders.

A one-time licence fee unlocks endless material possibilities beyond proprietary options. Researchers and manufacturing specialists gain the freedom to test novel materials, develop proprietary powders, or work with speciality third-party options.

Material testing becomes dramatically simplified with consistent hardware variables across experiments. Print settings remain fully customisable via the PreForm software, allowing parameter adjustments for exposure, layer thickness, and correction factors.

Production scalability remains unaffected, as open materials benefit from the same automated post-processing workflow. Fuse Sift extracts parts from unsintered powder in five minutes, and Fuse Blast delivers consumer-ready finishes within ten minutes of printing.

SLS advantages with Fuse 1+30W

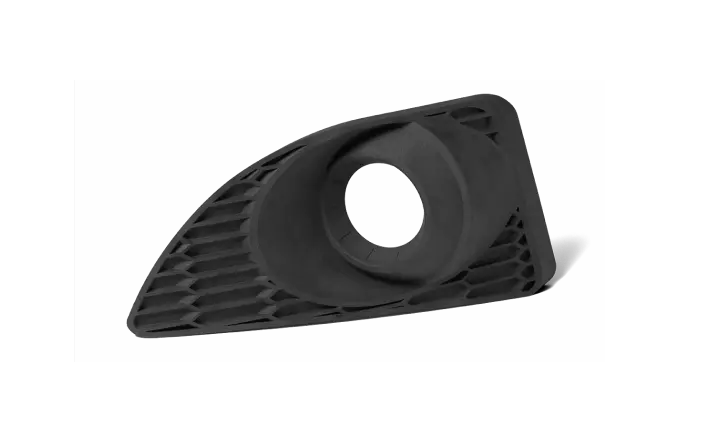

SLS technology eliminates support structures by suspending parts within unsintered powder during printing. Your complex geometries print without compromise, enabling previously impossible designs with internal channels, moving assemblies, and intricate details in single prints.

Parts maintain consistent properties regardless of orientation, allowing functional components to come directly from machines without secondary processing or reinforcement.

Production economics improve dramatically with high-density build packing. Multiple parts nest efficiently in the build volume, maximising throughput while minimising waste. You recover up to 80% of unused powder for subsequent prints, reducing material costs and environmental impact.

Rapid cooldown times of just 75 minutes between builds enable continuous production cycles, and adding a second removable build chamber creates an uninterrupted workflow. Your production capacity expands without additional machines, making the Fuse 1+30W ideal for prototyping and low-volume manufacturing.

Image credits: Formlabs