The Bambu Lab Automatic Material System is an airtight multi-material 3D printing solution with four spool holders with active filament control, a hub for merging filament paths, and a buffer for maintaining ideal filament tension.

It simplifies the print process, keeps your setup tidy, and allows for up to 16 colours or materials when using multiple AMS units.

The Bambu Lab AMS has three main components working in harmony:

Filament slots

The AMS has four individual filament slots or bays. Each slot contains:

- A motor and gears to feed or rewind the filament actively.

- A sensor to detect filament insertion, automatically pulling it in.

- The ability to rotate the spool when rewinding the filament.

Filament hub

Located at the base of the Bambu Lab AMS, the Filament Hub merges the four separate filament paths into one. It has:

- Four hall effect sensors to detect filament position.

- A magnetic rotary encoder.

- A brushless motor to apply a second driving force.

Filament buffer

The Filament Buffer connects the AMS to the 3D printer’s extruder. It includes:

- A sliding mechanism with a spring.

- A hall sensor to monitor the slide’s position.

- Controls to regulate the feed speed and maintain optimal filament tension for smooth extrusion.

Initial set up

The Bambu Lab AMS hits the ground running out of the box, with a pre-built shell and tubing tucked neatly inside. Connecting the tube and power control module to the back of the printer is all it takes to access AMS settings on your printer’s intuitive control interface.

Multiple LED indicators convey filament status—a breathing white light shows a tray is active, while a solid white means it’s loaded but idle. Should errors arise, the LED turns red, prompting you to check the messages.

AMS physical install steps

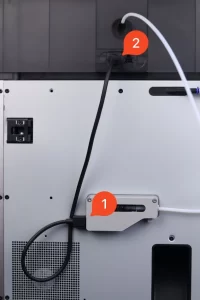

Connect the PTFE tube from the AMS to the filament buffer behind the printer, in the left PTFE connector.

Connect the PTFE tube to the right side of the filament buffer and then connect it to the back PTFE coupler that directs the filament to the extruder.

Connect one end of the 6-pin cable to the filament buffer and the other end to the first AMS slot

Connect one end of the 4-pin cable to the filament buffer and the other end to the printer.

Here’s a video:

When linking additional AMS units, Bambu Lab provides extension cables to unite them reliably and avoid messy tangling. To connect multiple Bambu Lab AMS units to one printer you will also need to replace the filament buffer with an AMS Hub which allows up to four AMS units to be connected.

Here’s a helpful video:

A few tips ensure a seamless multi-AMS setup:

- Keep PTFE tubing lengths below 3.5m to minimise resistance.

- Connect AMS units sequentially while powered on so they assign logically.

- If needed, you can view and reassign AMS ID numbers through the control interface.

For printing Bambu Lab’s built-in demo models, you must fill the AMS trays from left to right as prompted—a current limitation that means materials must map in that order.

Seamless software integration

Getting started is as simple as selecting an empty tray and pushing the button to insert a new filament. The AMS takes over, automatically loading material into the print head.

An RFID reader scans encoded Bambu Lab spools to sync filament type and colour settings in Bambu Studio without additional input.

The AMS Mapping interface displays the materials allocated to each tray, allowing tray-to-print role reassignment at a click. Print preparation is visual and intuitive – map the colours and materials needed by clicking the corresponding sources and destinations.

When sending a project to print, Bambu Studio automatically matches the required filaments to corresponding AMS trays—there is no need to map materials manually (again, saving you time and effort).

Unlocking advanced capabilities

The Bambu Lab AMS is a productivity powerhouse with the ability to queue and print with multiple colours and material types.

The humidity control system ensures even moisture-prone materials like PVA stay optimally dry, preventing compromised print quality due to moisture absorption. Failed prints and wasted spools caused by environmental humidity are issues of the past.

Should one of your material spools run out midway through a print job, the AMS can automatically transition to a fresh pre-loaded spool of that same filament without interruption. Your print carries on while you receive a notification to reload the emptied spool. No more aborting failed prints and restarting from scratch.