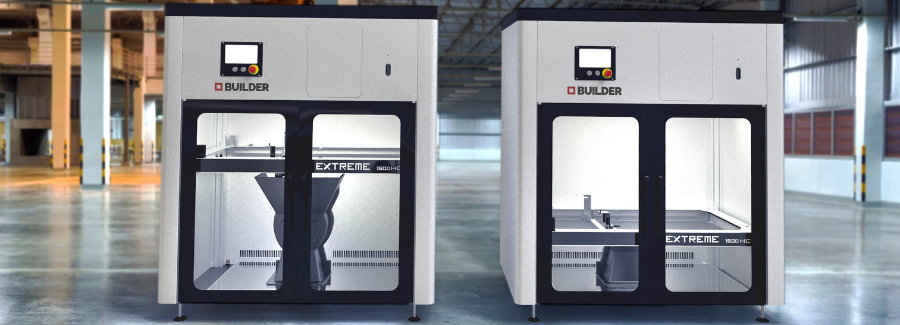

Large-format 3D printers have been around for some time. Since the 80s in fact, when manufacturers saw an opportunity to apply additive manufacturing to their production line. Decades later, its potential is still unfolding. There are now more large 3D printers than ever before, and it’s incredible what they can do.

From making true-to-scale car panels and aerospace prototypes to skyscraper signs, architectural mock-ups and 2-metre tall sculptures, large-format 3D printing has found use and purpose in every conceivable application.

Most large 3D printers are fused filament fabrication (FFF) printers, which means they extrude plastic onto a build plate in layers to make models.

The difference between machines comes in the quality of those prints and the speed at which they are made. Largely, this is determined by the quality of the extruder and stepper motors. Materials also play a role in print quality and speed.

Some large-format 3D printers support a wider range of materials than others. Most will print PLA and ABS. Others take things further with support for nylon, PET and more. Most of them also have an open filament system, meaning you can use third-party materials without voiding the manufacturer’s warranty, which is always a bonus.

In stockFormlabs Form 4BL 3D Printer Complete Package incl. 3 Year Service Plan£20,408.00 £24,489.60Next Working Day*

In stockFormlabs Form 4BL 3D Printer Complete Package incl. 3 Year Service Plan£20,408.00 £24,489.60Next Working Day* In stockFormlabs Form 4BL 3D Printer Premium Package incl. 5 Year Service Plan£30,758.00 £36,909.60Next Working Day*

In stockFormlabs Form 4BL 3D Printer Premium Package incl. 5 Year Service Plan£30,758.00 £36,909.60Next Working Day* Available to Order

Available to Order Available to OrderFormlabs Form 4L 3D Printer Complete Package incl. Wash L V2, Cure L V2 and 3 Year Service Plan£16,084.00 £19,300.80Stock due 22-10-2025

Available to OrderFormlabs Form 4L 3D Printer Complete Package incl. Wash L V2, Cure L V2 and 3 Year Service Plan£16,084.00 £19,300.80Stock due 22-10-2025 Available to OrderFormlabs Form 4L 3D Printer Premium Package incl. 5 Year Service Plan£26,265.00 £31,518.00Stock due 22-10-2025

Available to OrderFormlabs Form 4L 3D Printer Premium Package incl. 5 Year Service Plan£26,265.00 £31,518.00Stock due 22-10-2025 In stock

In stock Available to Order

Available to Order Available to Order

Available to Order Available to Order

Available to Order