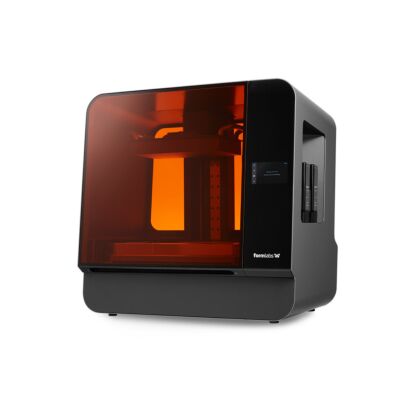

Formlabs Form 3BL Basic Package

- Print Big - build volume 5x larger than the Form 3B

- Small Details, Big Results - designed to print large scale, industrial-quality parts with fine details for professionals.

The Form 3BL is the large format dental 3D printer that raises the bar for dependable high-production dental 3D printing, designed to work day and night with minimal intervention.

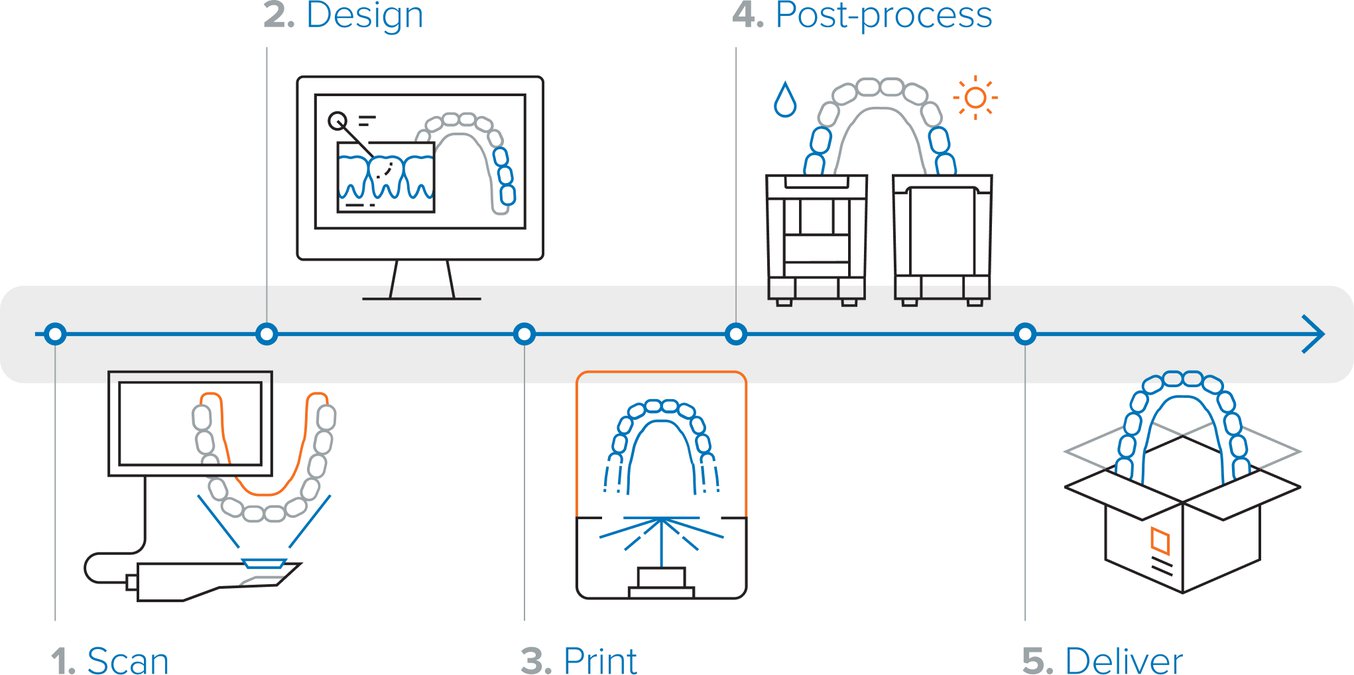

Digital Appliance Production You Can Rely On

Reclaim your time and produce parts you’ll be proud to deliver, without the hassle or prohibitive costs. Formlabs brings unprecedented reliability, quality, and ease of use, with validated workflows tested by a team of dental experts.

The Form 3BL is 5x larger than the Form 3B, but with the same technology so you get all of the Form 3B's reliability and consistency.

A build volume of 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in) maximizes throughput for every print job. Print up to 120 models in a day, with just a few printer interactions.

Intuitive and efficient

No specialized technicians required. The Form 3BL offers automatic resin dispensing, simple print preparation software, and a thoughtfully designed interface.

A Robust 3D Printing Ecosystem:

The Form 3BL works full time so you don’t have to. Intuitive nesting software and automated post-processing options make custom manufacturing easy.

High-resolution touchscreen interface:

A 5.5” interactive full-color display minimizes error and eliminates the need for constant monitoring.

Automated print setup:

Tested over millions of prints, free print preparation software, PreForm, automatically suggests optimal orientation, supports, and layout, with the ability to manually refine as needed.

Continuously evolving:

Formlabs believe the best products grow better over time, and they arecommitted to continually evolving our hardware through software improvements.

Designed for Nonstop Throughput

The Form 3BL is thoughtfully designed to maintain ideal print conditions with minimal operator intervention.

Cloud monitoring:

Remotely monitor and inspect your fleet of printers and track resin and tank usage over time with the online Dashboard.

Automatic resin dispensing:

Our automated resin system dispenses resin as parts print. The Form 3BL holds two cartridges of resin to avoid mid-print interruptions.

In-field repairs:

The Light Processing Units, rollers, optics window, and other components can be replaced in-house to ensure 24/7 uptime.

Status alerts

Enable SMS and email notifications to receive notifications when prints are completed or your printer needs attention.

Trusted by Dental Industry Leaders

With 75+ support and service staff and 150+ engineers, Formlabs backs its products with the strongest team in 3D printing.

Behind Formlabs Dental is a dedicated team of certified Dental Support Specialists who know exactly how to help when you need it. Our Dental Service Plan includes personalized onboarding training, proactive check-ins, and the best phone and email support in the industry.

Find out more about Low Force Stereolithography (LFS) ™

Part of the Formlabs Ecosystem

Formlabs is known for designing end-to-end additive workflows you’ll be excited to use. The Form 3BL brings the Formlabs experience to large format 3D printing. Form Wash L and Form Cure L

- Faster Printing - thanks to the Form 3BL's use of two, staggered, Light Processing Units (LPUs) used simultaneously to 3D print large prints.

- Powerful and Reliable - Low Force Stereolithography (LFS) for intuitive, versatile printing with easy support removal

- Biocompatible resins - developed and manufactured in an ISO 13485 certified facility.

- For the full eco-system purchase Form Wash L & Form Cure L

For more information about LFS technology and the Form 3B, please see this page, or contact our team on [email protected]/ 01765 694007

| Materials | Resins; Standard, Engineering , Flexible, Elastic, Tough, Durable, Jewellery, Specialty, |

|---|---|

| XYZ Resolution | X,Y: 25 microns / Z: 25 - 300 microns |

| Layer Height | 25-300 microns |

| Build Dimensions | 335 x 200 x 300 mm |

| Brand | Formlabs |

| Manufacturer SKU | PKG-F3L-WS-1 |

| Connectivity | WiFi, USB Cable, Ethernet Cable |

| Technology | Resin Printing (SLA) |

| System Requirements | Windows 7 (64-bit) and up Mac OS X 10.12 and up OpenGL 2.1 4 GB RAM (8 GB recommended) |

| Software | PreForm |

| Supported File Formats | STL and OBJ file input FORM file output |

| Weight (KG) | 48kg |

| Laser Specifications | 2 Light Processing Units EN 60825-1:2007 certified Class 1 Laser Product 405 nm wavelength 250 mW power 85 micron (0.0033 in) laser spot |

DELIVERY BY ADDITIVE-X

BOXES SHIP VIA DPD

Order by 4.30pm Monday to Friday (excl Bank Holidays) and Additive-X will ship your order via DPD the same day. DPD will deliver on working days only.

Depending on your postcode your options at checkout will include DPD NEXT DAY, DPD 12:00 and DPD 10:30 options. Some postcodes will show "DPD TWO DAY".

Shipping to Ireland (Northern or Republic of) is a “DAP” service which means you have to pay any Duty and Taxes. Business customers must email us their EORI and UKIMS numbers.

PALLETS DON'T SHIP VIA DPD - WHAT YOU NEED TO KNOW

Some units can only be shipped safely on a pallet due to weight and/or size. Cut off time for orders shipping by pallet is 1.30pm, that’s because we need to book the job before 2pm.

Pallets are big and they ship on big lorries! If there is any problem with a dustbin-lorry size vehicle accessing your property, you need to let us know and we can request delivery by a smaller 7.5T lorry. If this is the case, then PALLET NEXT DAY may not be available.

Depending on your postcode your options at checkout will include PALLET NEXT DAY, PALLET 2-3 DAYS, PALLET COLLECTION HG4 2RN (organise your own pick-up). Some postcodes will show “PALLET 5-6 DAYS” etc.

Pallet deliveries are between 09.00 and 17.00 and we are unable to give you the ETA in advance.

We use a very reliable local supplier, and the pallets go in to the “Palletforce” network. Currently the network don’t use tracking numbers and you can't track online (coming in 2026). Call or email us to check on a delivery or collection.

UK Mainland - Box Shipping

|

COLLECTION HG4 2RN |

£0.00 |

FREE of charge, Mon-Fri 9-5.30pm Collect from Additive-X, Ripon Call 01765694007 to arrange |

|

DPD NEXT DAY |

£7.80 |

FREE on orders over £100 excl VAT |

|

DPD 12:00 |

£14.40 Excl VAT £12.00 |

UK mainland - excl offshore and extended areas Order by 4.30pm Mon-Fri |

|

DPD 10.30 By 10.30 Next Working Day |

£21.00 Excl VAT £17.50 |

UK mainland - excl offshore and extended areas Order by 4.30pm Mon-Fri |

|

DPD Saturday |

£21.60 Excl VAT £18.00 |

UK mainland - excl offshore and extended areas Order by 4.30pm Fri |

|

DPD Two Day |

£15.00 Excl VAT £12.50 |

2-3 day service - UK offshore and extended areas Order by 4.30pm Mon-Fri |

|

DPD Two Day |

£25.00 Excl VAT £20.83 |

2-3 day service Jersey, Guernsey, Isle of Man Order by 4.30pm Mon-Fri |

|

DPD TO IRELAND |

£25.00 Excl VAT £20.83 |

Requires EORI and UKIMS, customer pays Tax & Duties 2-3 day service |

UK Mainland - Pallet Shipping

|

PALLET COLLECTION HG4 2RN |

£0.00 |

FREE of charge, Mon-Fri 9-5.30pm Call 01765694007 to arrange |

|

PALLET NEXT DAY *order by 1.30* |

£102.00 Excl VAT £85.00 |

Next Day Pallet Service Mon-Fri (excl postcodes in zone 7). Must be booked by 1.30pm. Delivery between 9-5pm |

|

PALLET 2-3 DAYS |

£66.00 Excl VAT £55.00 |

Economy Pallet Service Mon-Fri (excl postcodes in zone 7). Delivery between 9-5pm |

|

PALLETS TO ZONE 7 POSTCODES |

Economy Pallet Service Mon-Fri |

Delivery between 9-5pm |

|

AB, IV1-40,52-52,57+ |

£155.00 |

4-5 Day Delivery |

|

DD |

£135.00 Excl VAT £112.50 |

3-4 Day Delivery |

|

IV41-51,55-56, KA27-28 |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

KW1-14 |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

HS, KW15-17 |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

PA20+ |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

PH1-7, 14 |

£135.00 Excl VAT £112.50 |

3-4 Day Delivery |

|

PH 8-13,15+ |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

ZE |

£275.00 Excl VAT £229.17 |

7-8 Day Delivery |

|

IM |

£225.00 Excl VAT £187.50 |

5-6 Day Delivery |

|

IM |

£225.00 Excl VAT £187.50 |

5-6 Day Delivery |

|

PO30-41 |

£155.00 |

5-6 Day Delivery |

|

GY AND JE (EXCL. GY9) |

£175.00 Excl VAT £145.83 |

5-6 Day Delivery |

|

PALLETS TO IRELAND, GUERNSEY GY9, JERSEY |

Ask for a Quote |

Need more information on delivery and returns? Please visit our full delivery page.