Formlabs Clear Resin produces transparent parts with minimal yellowing for visual prototypes, fluid flow testing, and optical applications.

You can now choose between two versions of this popular material: Clear Resin V5 for Form 4 series printers and Clear Resin V4.1 for earlier models.

Both versions deliver high-clarity parts with near-optical transparency after polishing to showcase internal features or create functional prototypes.

Resins in this article:

What makes Clear Resin special

Clear Resin creates stiff, strong parts with mechanical properties comparable to acrylic. The newest V5 formulation prints three times faster than previous versions while maintaining exceptional clarity.

When properly post-processed, parts exhibit minimal colour cast, unlike many competing transparent materials that show pronounced yellowing.

Transparent surfaces can be achieved through careful finishing with progressive sanding followed by spray coating or polishing.

Watch this video to find out more:

Clear Resin V5 vs Clear Resin V4.1

Clear Resin V5 works exclusively with Form 4 series printers, offering significant advantages over the V4.1 formulation.

Thanks to optimisations for the Low Force Display technology in Form 4 printers, the V5 version prints faster. Clear V5 delivers 8% elongation at break compared to only 4% with V4.1, making parts more damage-resistant during handling and use. The newer formulation also provides higher impact strength measured by notched Izod testing.

Key technical specifications

Formlabs Clear Resin V5 achieves 60 MPa ultimate tensile strength when post-cured at 60°C for 15 minutes, exceeding many injection-moulded plastics. The material maintains a tensile modulus of 2750 MPa, creating rigid parts that resist deformation under load.

With proper curing, flexural strength reaches 105 MPa, allowing thin-walled sections to bear substantial weight without breaking. The heat deflection temperature measures 74°C at 0.45 MPa, making parts suitable for moderate-temperature environments.

Applications suited for Clear Resin

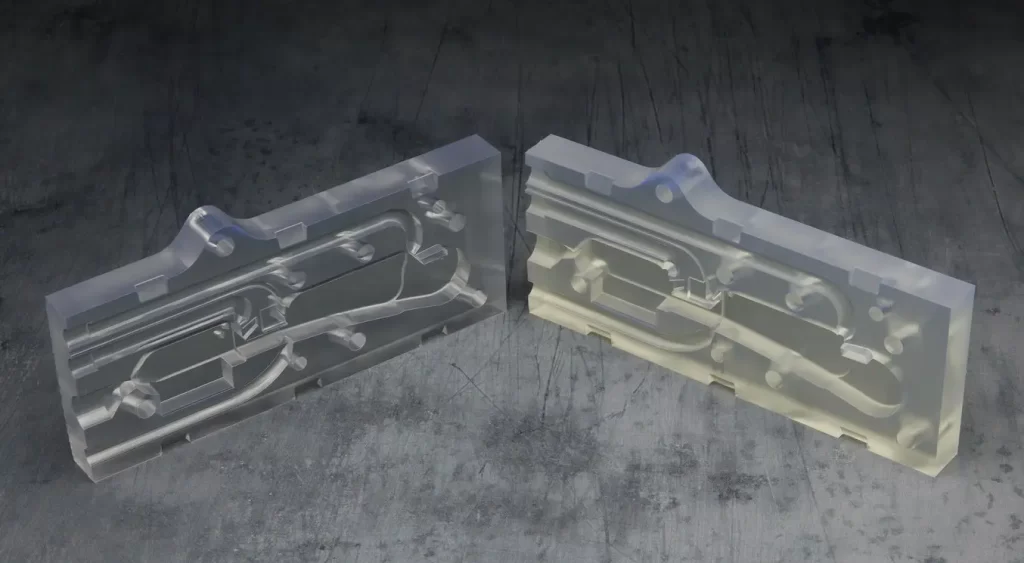

Clear Resin’s transparency benefits medical device prototypes, revealing internal mechanisms without disassembly. Fluid flow devices like microfluidic chips allow direct observation of liquid movement through channels and testing of capillary action.

Lighting prototypes exploit light transmission properties, mainly when testing diffusion, reflection and distribution patterns.

Educational models displaying internal structures help students visualise complex assemblies while protecting delicate components from handling damage.

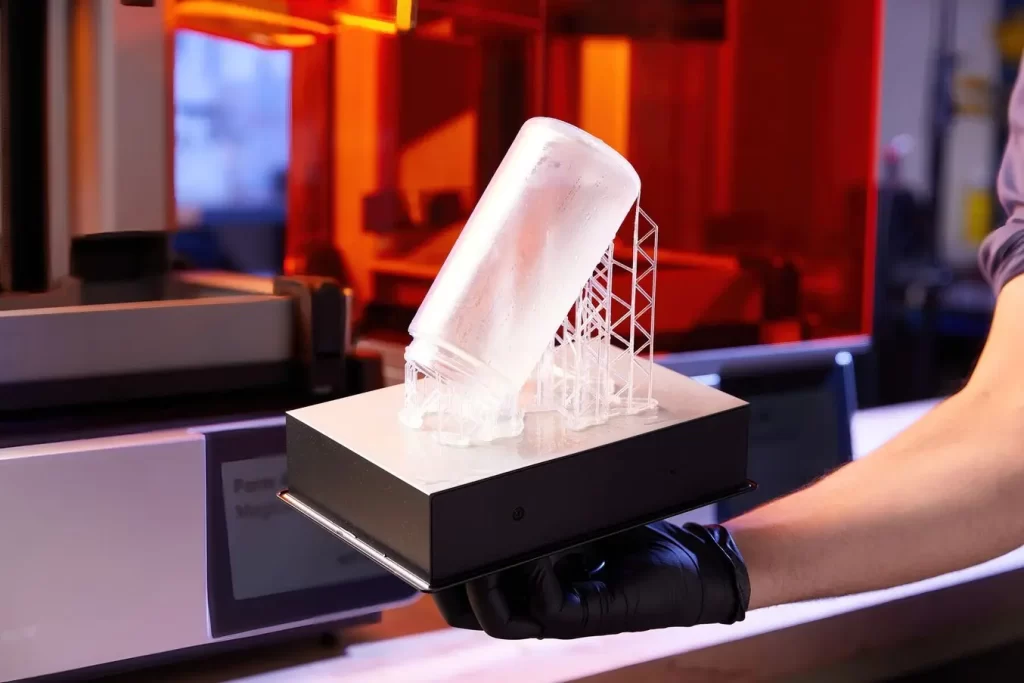

Printing with Clear Resin

You need the appropriate resin tank for your printer model. Form 4 printers require Form 4 Resin Tanks designed explicitly for Clear V5.

Before starting any print job, set your PreForm software to the correct resin type and position models to minimise visible support marks on critically transparent surfaces. Layer heights of 50 or 100 microns work best for most applications, balancing detail with reasonable print times.

Essential post-processing steps

Washing Clear Resin parts ensures maximum transparency. For optimal results, immerse freshly printed parts in isopropyl alcohol for 5 minutes using Form Wash. Remove support structures after washing while the Resin remains slightly pliable.

Post-curing improves mechanical properties, though Formlabs Clear Resin V5 makes this step optional for non-critical applications. Cure parts for maximum strength and optical clarity for 15 minutes at 60°C in Form Cure.

Achieving crystal-clear finishes

Properly processed Clear Resin appears slightly frosted directly from printing. You can achieve glass-like clarity through progressive wet sanding from 400 to 3000 grit, followed by polishing compound application.

Spray coating provides an alternative finishing method requiring less manual effort. Apply two thin coats of clear acrylic spray, allowing proper drying between applications. Avoid touching surfaces after final finishing to prevent fingerprints that compromise transparency.

Solving common issues with Clear Resin

Yellowing typically results from inadequate washing or excessive UV exposure during post-curing. Ensure thorough alcohol washing and follow recommended curing times precisely.

Cloudy areas within prints usually indicate trapped uncured resin, which is particularly problematic in thick sections or enclosed cavities. Design drainage holes for hollow prints and extend washing time for complex geometries.

Bubbles can form during pouring or settling in the resin tank, so allow Resin to rest 30 minutes before printing after tank refills.

Industry-specific uses

Automotive prototypes use Clear Resin for headlight assemblies, allowing assessment of light distribution patterns.

Consumer product developers create transparent housings to evaluate internal component layouts. Jewellery designers print clear masters to cast transparent gems or create silicone moulds for resin casting.

Research laboratories produce custom fluid handling devices, reaction chambers and observation cells without expensive machining operations.

Extending the shelf life of Formlabs Clear Resin

Store unopened cartridges in cool, dark environments away from direct sunlight at temperatures between 10-25°C. When covered with tank lids, the resin remaining in tanks stays usable for up to three months.

If left in tanks for extended periods, filter resin periodically using 190 micron fine-mesh filters. Check for signs of overexposure, such as increased viscosity or colour change, which indicates the material has begun polymerising prematurely.

Compatibility with Formlabs printers

Clear Resin V5 works exclusively with Form 4, Form 4B, Form 4L and Form 4BL printers. Clear Resin V4.1 is available for Form 3, Form 3+, Form 3B, Form 3B+, Form 3L and Form 3BL models.

Both versions require printer-specific resin tanks and compatible build platforms. Never mix resin formulations between printer generations, as print settings and light engine specifications differ significantly between models.

Formlabs continues improving Clear Resin with each generation, focusing on faster print speeds, better optical clarity and stronger mechanical properties.

The material remains essential for applications requiring transparency while benefiting from the precision and reliability that make Formlabs printers industry standards.