Essential Tips on Cleaning and Maintaining Your 3D Printer’s Nozzle

3D printing technology is revolutionising various industries, from architecture to healthcare, education to culinary arts. But crucial to owning a 3D printer is regular maintenance to keep it in working condition. One essential component that needs special attention is the nozzle.

The nozzle is a critical part of your 3D printer – it’s the last path your filament travels through before it forms your print. A clogged or dirty nozzle could mean poor quality prints or, even worse, failed print jobs. It also puts unnecessary stress on the printer’s other components, potentially leading to more frequent maintenance or replacements. Hence, having a clean nozzle is very important for a smooth printing experience.

Routine Nozzle Cleaning

Cleaning your 3D printer’s nozzle should be part of your regular maintenance routine. Here’s a simple step-by-step guide:

- Visually inspect the novel for any apparent dirt or burnt plastic.

- Heat your printer ( usually in preheat mode) and then gently clean the exterior of the nozzle with a brass wire brush or a light abrasive pad. Be cautious to avoid damaging any heater or sensor wires.

Remember, regular cleaning will keep your nozzle free from stubborn dirt that could otherwise accumulate and cause a clog.

How to Handle a Jammed Nozzle

Despite regular cleaning, your nozzle can still jam due to filament snapping or other maintenance failures. Here’s how to handle this:

- Disassemble the hot end and nozzle of your printer (use your printer’s manual for guidance).

- Submerge the disassembled parts in acetone, if you mostly use ABS filament. The solvent usually dissolves the ABS or at least softens it for easy removal.

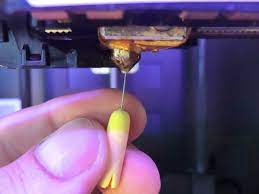

- For other materials (PETG, PLA, Nylon), heat the parts for a few minutes, melt the material, and use a needle to remove blockages gently.

Remember, dealing with jams requires patience and care to avoid damaging your printer.

The Cold Pull Method for Cleaning

This method involves using a special cleaning filament. The filament is passed through a heated, then cooled nozzle, and upon removal, it takes with it any residual dirt or clog. You can refer to detailed video guides online for a walkthrough of the process.

Preventing Nozzle Clogs

Prevention is better than cure, and it’s the same with your 3D printer’s nozzle. You should use high-quality filament, clean your nozzle regularly, and also avoid sudden temperature changes to prevent clogs. Developing a routine maintenance schedule for your printer will go a long way in keeping it in prime condition.

FAQs on Nozzle Cleaning You might still have questions on nozzle cleaning, and we’ve answered some common ones for you:

- Do you need to clean the nozzle after each print? No, but regular cleaning is advisable to maintain optimal printer performance.

- Can you use water to clean the nozzle? It’s better to use a cleaning solution like isopropyl alcohol. Water could cause rusting or corrosion.

- Can the nozzle be replaced? Yes, if it’s damaged or worn out. Ensure you use the right size and type for your printer.

Keeping your 3D printer’s nozzle clean is essential to guaranteeing high-quality prints, as well as maintaining the overall longevity of your printer. We hope that the tips and techniques discussed in this post will help you maintain your nozzle effectively. Happy printing!