Your Bambu Lab X1E printer includes three build plate options because each material and print job has different surface requirements.

The Textured PEI’s rough surface creates an incredible mechanical grip, perfect for materials that typically warp or detach. Meanwhile, Smooth PEI is essential when you need parts with machined-looking finishes and precise tolerances. The 3D Effect plate is for aesthetic projects, imprinting unique patterns into the bottom layer.

Join us below for tips on choosing the right Bambu Lab X1E build plate for your project.

In this post:

- Bambu Lab Textured PEI Plate

- Bambu Lab Dual-Sided Smooth PEI Plate

- Bambu Lab 3D Effect Sheets Combo with Plate

A closer look at the Textured PEI Plate

The Textured PEI Plate stands out with its exceptional first-layer adhesion capabilities. The powder-coated surface eliminates the need for adhesives with most materials. The rugged texture transfers to your prints, giving them a distinctive finish that’s particularly appealing for functional parts.

Why choose it

Offers excellent adhesion without the need for glue, saving you time and hassle. The plate has improved durability, maintains structural integrity at high temperatures up to 180°C. Parts self-release once the plate has cooled to room temperature, perfect for engineering materials. Plus, the textured finish adds a professional touch to your functional parts.

A closer look at the Smooth PEI Plate

The Smooth PEI Plate excels at precision printing with superior Z-axis accuracy. The specialised matte PEI sheet creates a silky-smooth bottom surface finish. Its 0.5mm spring steel plate enhances magnetic adhesion, helping prevent warping even on large prints.

Why choose it

For parts that need to fit together perfectly, you’ll achieve tighter tolerances and better dimensional accuracy.

The smooth surface creates a professional, factory-like finish on your prints. It’s especially valuable when you need parts with impeccable surface quality from the printer

A closer look at the 3D Effect Plate

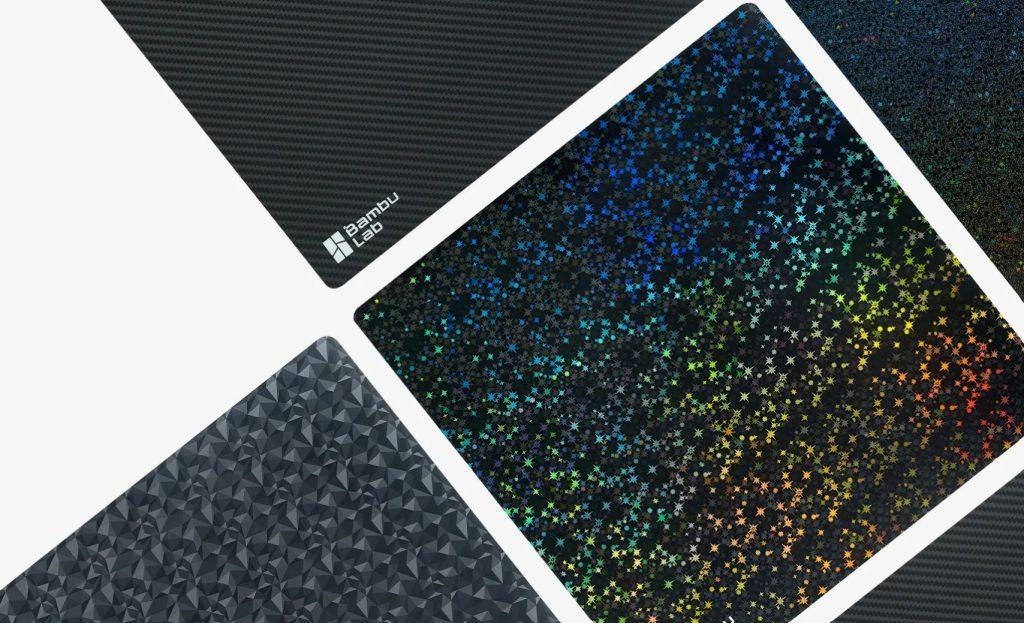

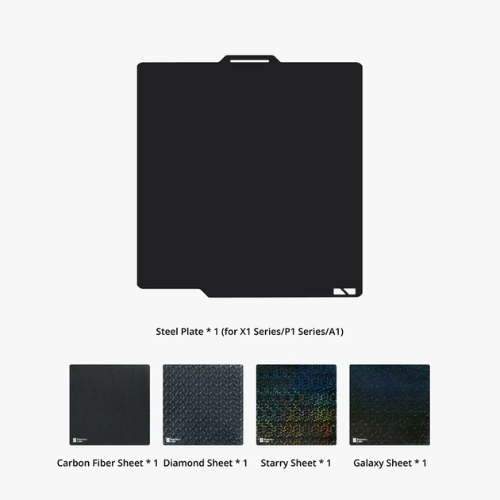

The 3D Effect Plate has four distinct texture options that transform your prints. Choose between Galaxy’s vibrant rainbow effect, Carbon Fibre’s subtle weave pattern, Starry’s kaleidoscope glitter, or Diamond’s mix of glossy and matte finishes. These patterns transfer directly to your print’s first layer.

Why choose it

You can create visually stunning prints that catch the eye and change appearance depending on the viewing angle. The effects work particularly well with silk and shiny filaments, letting you produce models with unique surface textures impossible to achieve with standard plates.

Temperature considerations

Temperature compatibility varies between plates. Your Textured PEI handles up to 180°C, while the Smooth PEI tops at 120°C. For the 3D Effect Plate, stick to lower-temperature materials like PLA and TPU to preserve the transfer patterns.

Setting up your build plate Installation follows the same straightforward process for all plates: align with the fixed points facing you, then lower onto the magnetic platform. The spring steel construction ensures reliable magnetic adhesion, which prevents warping during those long, high-temperature prints.

Keeping your plates in top condition

The Textured PEI needs regular cleaning with detergent and water, while the Smooth PEI benefits from occasional light sanding to restore adhesion.

Your 3D Effect Plate requires extra care. Avoid using glue, and be gentle with the scraper to preserve those intricate patterns.

Material compatibility and adhesion Material compatibility spans the entire Bambu Lab X1E filament range, but you’ll need to adjust your approach.

The Textured PEI handles most materials without adhesives, except for TPU and some engineering plastics. Your Smooth PEI requires glue for anything beyond PLA, and the 3D Effect Plate works best with PLA and TPU exclusively.

Understanding plate lifespan

Remember that all three plates are consumable parts – they’ll naturally degrade over time. Regular maintenance and proper handling extend their lifespan but expect to replace them periodically, especially if you’re running your X1E continuously.

Working with calibration systems The Bambu Lab X1E’s Micro Lidar calibration works flawlessly with both PEI plates, but due to its reflective surface, you’ll need to skip this step with the 3D Effect Plate. Keep this in mind when switching between plates in your workflow.

Making your final choice

Choosing between these plates ultimately comes down to what you’re building. The Textured PEI delivers unmatched reliability if it’s engineering parts and functional prototypes. When dimensional accuracy is paramount for engineering components, reach for the Smooth PEI.

The 3D Effect Plate transforms ordinary models into showpieces when your prints need extra visual impact with a textured surface.