It’s impossible to miss Bambu Lab when shopping for an entry-level desktop 3D printer, thanks to its accessible pricing for printers with premium features.

But it’s the Bambu Lab ecosystem that really sets these machines apart, leapfrogging other keenly priced brands with a premium hardware and software experience.

All Bambu Lab desktop 3D printers use Fused Filament Fabrication (FFF) technology, extruding melted thermoplastic material through a nozzle to construct three-dimensional objects layer by layer.

You control the print process in Bambu Studio on Windows or MacOS, including slicing and print management. Alternatively, Bambu Handy, the company’s mobile app for Android and iOS, provides mobile management on the go.

And that’s not all—Bambu Lab makes its filaments (PLA, PETG, ASA/ABS, to name but a few) and innovates with new accessories, like the Bambu Lab AMS (Automatic Material System), which has four spool holders with active filament control, a hub for merging four filament paths, and a buffer for maintaining ideal filament tension.

The beauty of all this is that Bambu Lab makes 3D printing so easy—we’re talking filament presets, self-test program guides to diagnose equipment problems, one-touch printing, and built-in controls on the printers themselves.

We provide more colour on all these things below.

Bambu Lab 3D Printer Range

A1 Series

The A1 Series includes the A1 and A1 Mini, two stripped-down 3D printers without an enclosed chamber, designed for ease of use and quality output.

Headlines specs include a 256 x 256 x 256 mm build volume, an extrusion temperature reaching up to 300 C, and a bed temperature of 100 C, making it compatible with a wide range of materials like PLA, PETG, TPU, PVA, and HIPS.

The A1 has full auto calibration, eliminating the need for manual adjustments of bed level, Z-offset, and other settings. It also has active flow rate compensation and high-speed precision, allowing for smooth, accurate prints even at high speeds.

The A1 has an optional AMS lite system for multi-colour printing and offers quick-swap nozzles for easy maintenance. Its all-metal frame and rails ensure reliability and longevity. The printer operates quietly, with noise levels under 48 dB in silent mode.

User-friendly features include an intuitive touchscreen interface and compatibility with the Maker World platform for one-click printing.

The A1 also supports remote control and monitoring through the Bambu Handy app and has a 3.5-inch 320 x 240 IPS touchscreen.

The A1 Mini has the same features but in a smaller package – you’re looking at a build volume of 180 x 180 x 180 mm (perfect for small desks), although this printer lacks an air filter (for that, you need the P1 or X1 Series).

P1 Series

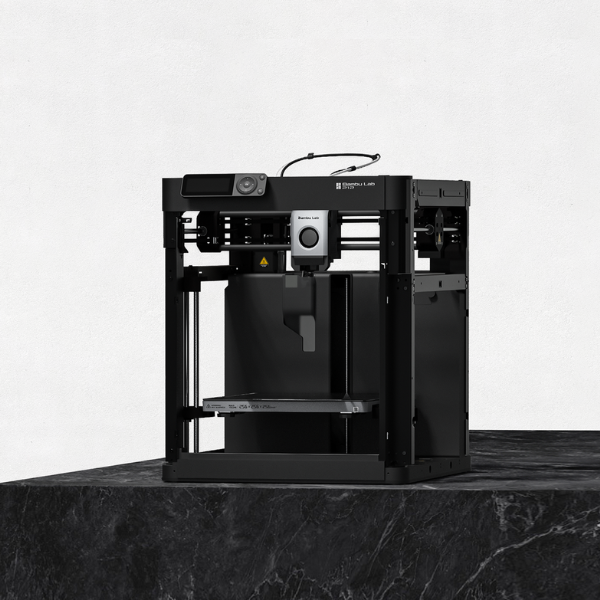

The P1 Series includes the P1P and P1S.

The P1P is a non-enclosed variant of the P1S, with the same capabilities and build volume but optional cooling (we go into the types below).

Both models include filament run-out detection, power loss recovery, and a 1280 x 720 camera with timelapse support.

The P1S is a step up from the A1 in terms of capability, adopting an enclosed (non-heated) build chamber for wider filament compatibility – ABS and ASA are ideal materials, and it’s capable of printing PA, PC, and PET, while these aren’t recommended for the A1.

It shares the same 256 x 256 x 256 mm build volume as the A1, but it has additional cooling via a chamber temperature regulator fan and MC board cooling fan.

The result of that enclosed chamber is the ability to print more materials and tighter control over quality, which is especially important if your printer lives in a dusty environment. You also get an activated carbon filter to trap airborne particulates.

The only downside to the P1S over the A1 is it only gets a 2.7-inch 192 x 64 screen, which is smaller and lower-res than the A1’s 3.5-inches.

X1 Series

The X1 Series includes the X1 Carbon and enterprise-oriented X1E.

The X1 Carbon is the ultimate Bambu Lab printer with a hardened steel nozzle, extruder gears, and a higher max build plate temp of 110 Cat 220 V and 120 C at 110 V (the A1 and P1 Series hit 100 C max).

What do these beefed-up specs get you? Complete compatibility with PA, PC, PET, polymer materials, and carbon/glass-reinforced filaments.

This printer also has Bambu Micro Lidar, a significant innovation that brings micrometre precision into your 3D printing workflow. The system probes the nozzle height, calibrates the flow, and scans the first layer to assure quality.

Additionally, the X1 Carbon has the best in-built controls, with a 5-inch 1280 x 720 touchscreen that looks gorgeous and is a snap.

The X1E is an additional upgrade. Its nozzle temperature is 320°C, while the X1C maxes out at 300°C. It also has a built-in chamber heater that can heat up to 60°C, which the X1C lacks.

The X1E also has enhanced network security features, including an Ethernet port, removable Wi-Fi module, and enterprise-grade network access control.

The X1E has superior air filtration with a G3-grade pre-filter, H12-grade HEPA filter, and particulate matter filtration compared to the X1C’s activated carbon filter.

Bambu Lab AMS

The Automatic Material System (AMS) is an optional system for the X1 and P1 series. The AMS has four individual filament slots or bays.

Each slot contains:

- A motor and gears to feed or rewind the filament actively

- A sensor to detect filament insertion, automatically pulling it in

- The ability to rotate the spool when rewinding the filament

The AMS unit has a humidity Sensor, air-tight seal and user-replaceable desiccant packs to protect moisture sensitive materials.

It communicates with the printhead to ensure smooth feeding and automatic filament change at mid-print. It can detect the filament tension and actively adjust the feed rate – perfect for automated, high-quality prints.

It supports all Bambu Lav filament, including PLA, PETG, ABS, ASA, PET, PA, PC, PA, PP, POM, HIPS and Bambu PLA-CF / PAHT-CF/ PETG-CF.

Bambu Lab Software

Bambu Lab has two excellent software products:

Bambu Studio

Bambu Studio is an open-source slicing software for 3D printing that offers advanced features and an intuitive interface.

It supports project-based workflows, allowing users to manage complex multi-part projects efficiently, and the software optimises print quality at high speeds through features like “Arch Move” and smart cooling.

You can enable multi-colour printing with versatile colorising tools and automatic filament mapping. The software also supports the STEP file format, offering higher accuracy and preserving assembly relationships.

It provides remote control and monitoring capabilities for 3D printers over networks, and there’s a 3D text tool for the easy creation of personalised text shapes within projects, which is ideal for speeding up personalisation workflows.

Bambu Handy

Bambu Handy is Bambu Studios’ mobile app for Android and iOS devices. It allows you to control and monitor Bambu Lab 3D printers remotely.

You can monitor the printing process, control printers from anywhere, and manage printer settings directly from your smartphone. The app provides error-checking and real-time reporting of any issues during printing.

It automatically records the printing process to help diagnose any failures, and the app can create automatic timelapse videos of prints that can be shared with others.

Overall, Bambu Handy is a fantastic complimentary app to Bambu Studio, enabling remote management anywhere with an internet connection.

Top image: Bambu Lab P1P with Pixel Modplate (a 3D printable item)